As industrial manufacturing demands higher precision and efficiency for products, 6kW laser cutting technology has gradually become a core tool in the metal processing industry, thanks to its advantages of high precision, high speed, and strong adaptability.

Next, we will explore the principle, advantages, and diverse applications of this technology in depth.

1. Technical Definition & Principle

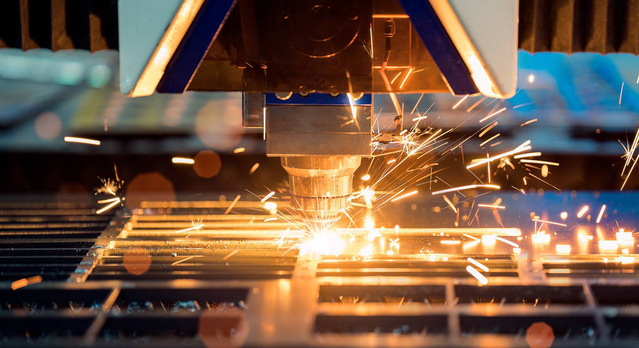

6kW laser cutting refers to a processing technology that uses a high-energy laser beam with a power of 6000 watts (6kW) to melt or vaporize metal materials, and blows away the molten material with auxiliary gas to achieve cutting.

Its core lies in highly focusing the laser beam to form a light spot with extremely high energy density, which is processed under the precise control of a CNC system.

2. Key Technical Advantages

- High Precision: The light spot is fine, enabling millimetric (with a diameter less than 0.1mm) or even micrometric precision cutting, suitable for processing complex contours such as electronic components and medical devices.

- High Efficiency: Compared with low-power equipment, the cutting speed for medium and thick plates is significantly improved (e.g., the speed for 6mm carbon steel can be 2-3 times that of low-power equipment), greatly shortening the production cycle.

- Wide Material Adaptability: Through parameter adjustment, the same equipment can process various metals such as stainless steel, aluminum alloy, and brass, as well as some non-metallic materials.

- Minimal Thermal Impact: The local heating method reduces material thermal deformation, which is particularly important for precision processing of high-strength alloys in aerospace and other fields.

3. Core Technologies & Components

- Fiber Laser: As the core component, compared with traditional CO₂ lasers, it has the advantages of high electro-optical conversion efficiency (up to 40%), better beam quality (enabling finer focused light spots), and low maintenance costs.

- Intelligent Cutting Head: Built-in intelligent sensing system that can real-time monitor the focal position and the distance from the material surface, and automatically compensate for plate unevenness.

- Auxiliary Gas Control System: Can dynamically adjust air pressure according to material thickness to optimize cutting quality.

4. Typical Application Scenarios

- Metal Plate Processing: Such as body panels and chassis brackets in automobile manufacturing. The cut surface is smooth without the need for secondary processing.

- Precision Instrument Manufacturing: Such as titanium alloy components of medical devices and metal casings of electronic equipment. Laser cutting can achieve micrometric tolerance control.

- Mold Repair & Transformation: Laser cutting can directly engrave complex cavities, shortening the mold development cycle.

5. Development Trends

6kW laser cutting technology is deeply integrated with automation and intelligence. By integrating visual recognition systems, it realizes automatic plate positioning and cutting path correction; combined with industrial robots, it achieves the development of unmanned production from coil materials to finished products.

In balancing precision and efficiency, 6kW lasers remain the mainstream choice for medium and thick plate processing, continuously promoting the manufacturing industry towards a more efficient and precise direction.

We hope the above summary is helpful to you. If you need in-depth understanding or query other information, our professional technical team is ready to answer your questions at any time.