The previous issue introduced four core applications of laser technology in the field of industrial manufacturing.

Now, let’s provide a detailed explanation of the other three core applications: laser cutting, laser welding, and laser wire stripping.

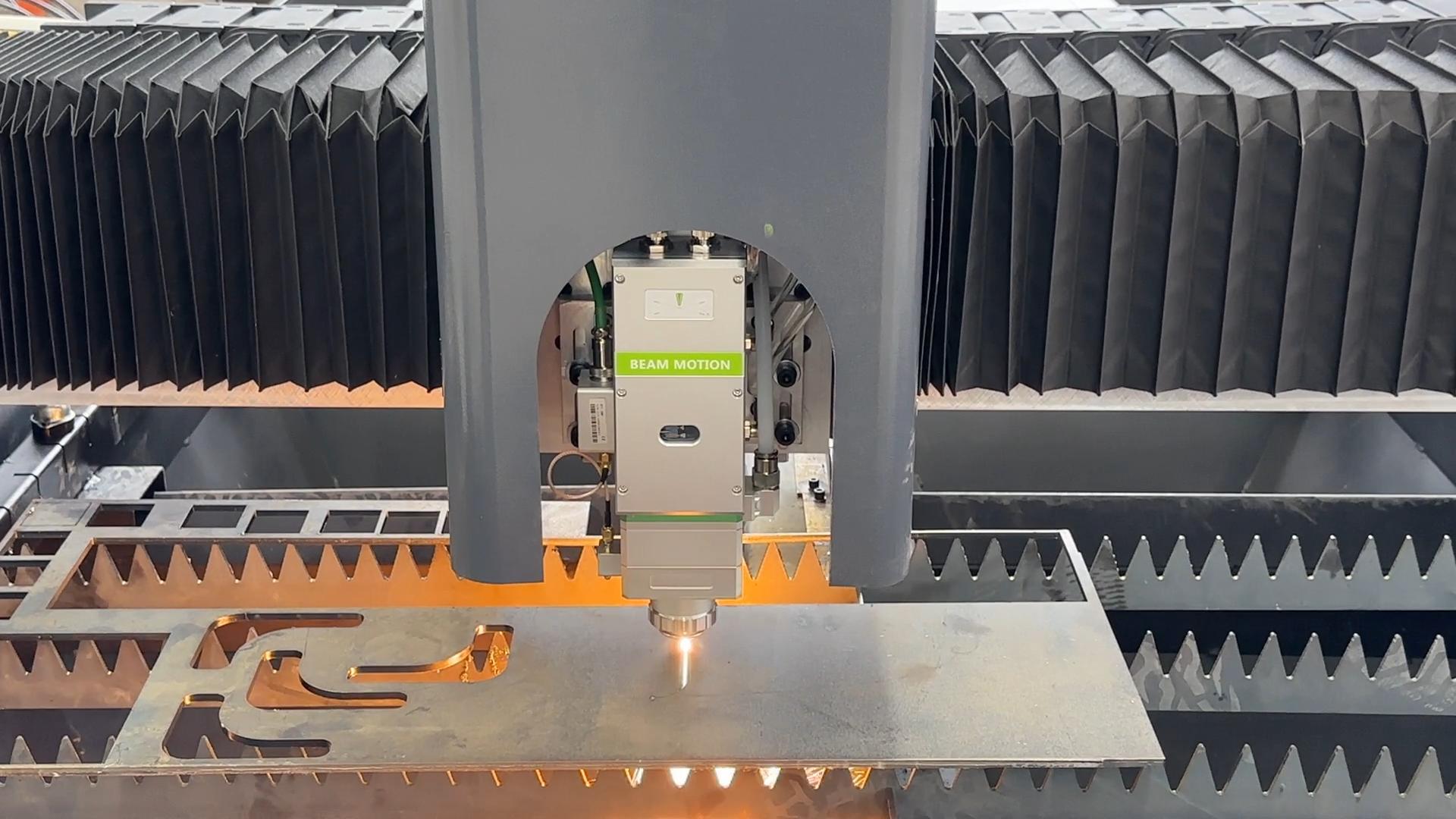

5. Laser Cutting

Similar to laser drilling, laser cutting uses focused laser beams to precisely ablate materials, enabling straight cuts or custom-patterned cuts with controlled depth.

Ultrafast lasers are commonly used for processing metals (e.g., aluminum, titanium, steel) and polymers, delivering clean edges without heat-affected zones (HAZ) and micron-level tolerance control.

Robotic laser cutting—equipped with robotic arms, material positioners, controllers, and end-of-arm tools (EOAT)—enables multi-directional, multi-angle flexible cutting. This technology holds significant market potential with steady growth expected.

However, widespread adoption requires advancements in product differentiation, cost reduction, and supply chain optimization. Companies must invest in R&D, build strategic partnerships, and adapt to changing market demands to capitalize on emerging opportunities.

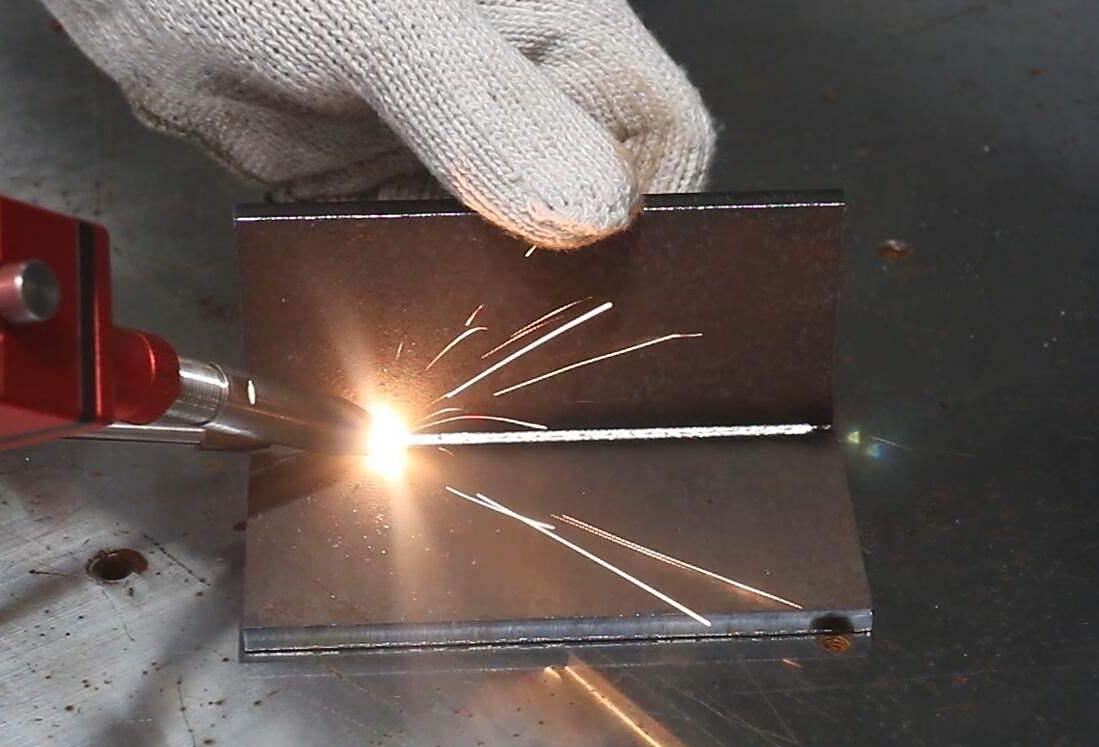

6. Laser Welding

Laser welding is an advanced fusion welding process that joins metals or thermoplastics using focused laser beams. By concentrating high-intensity laser energy on the joint area, the material edges melt and fuse to form a strong seam.

This technology excels at joining complex geometries and dissimilar materials, making it suitable for industries ranging from aerospace and medical devices to fine jewelry.

Laser welding offers numerous advantages:

significantly faster speeds than traditional methods (up to 4x faster than TIG welding in some applications), non-contact processing (heat delivered via laser beam), high precision (capable of joining materials with large thickness variations), and reduced thermal distortion due to lower total energy input—eliminating the need for additional cooling components.

It is compatible with a wide range of materials, including copper and plastics, and adjustable parameters allow for customized weld size and depth. Welds produced by laser welding are aesthetically comparable to professional TIG welding, yet easier to execute and faster. In many cases, post-weld grinding can be omitted without compromising appearance.

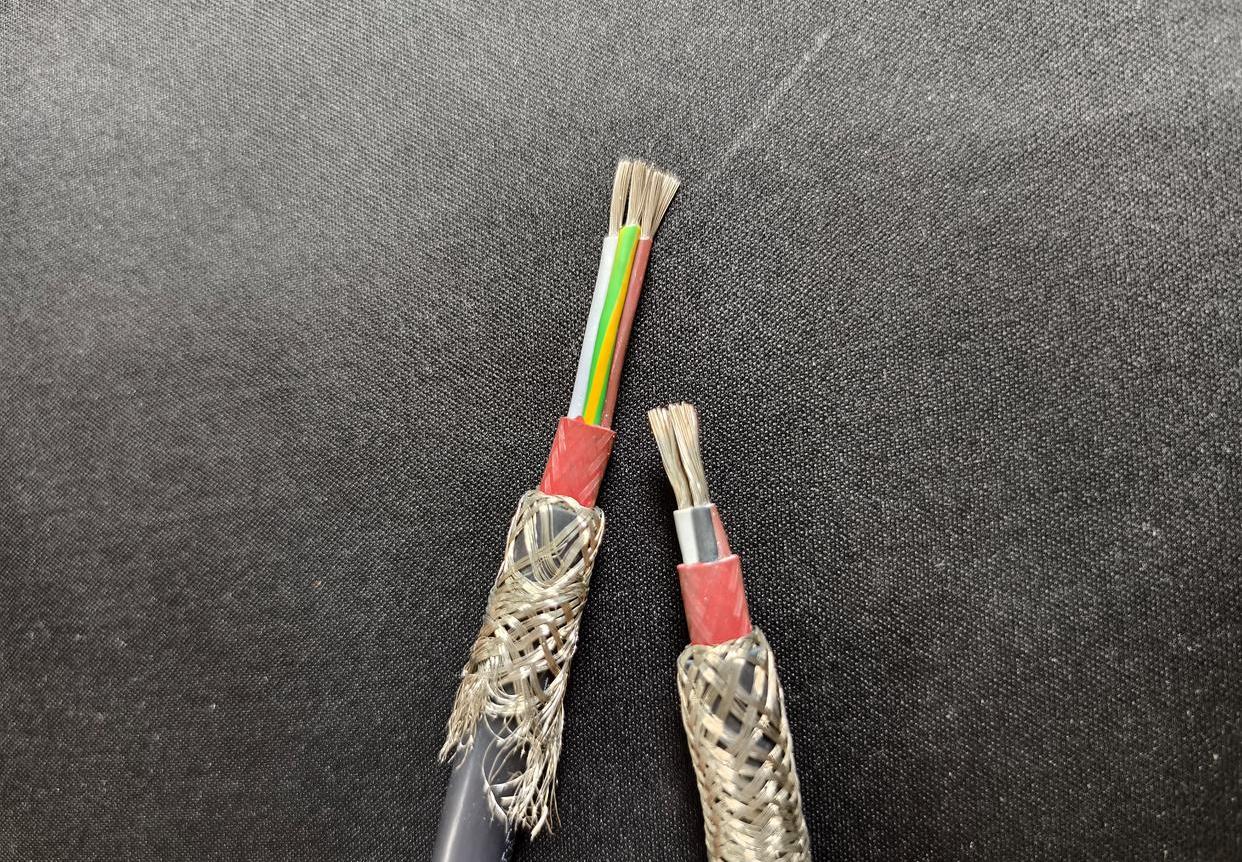

7. Laser Wire Stripping

Laser wire stripping is a fast, non-contact process that delivers exceptional precision and process control. It can handle fine wire gauges (down to 32 AWG) with insulation removal accuracy within tight tolerances. Programmable functionality allows for precise mid-span stripping by ablating insulation at any point along the wire.

In medical device manufacturing, laser stripping has become the standard method for removing insulation or coatings from wires, catheters, and other components. Its key benefit is highly repeatable quality.

Using CO₂ lasers, the process efficiently ablates polymer insulation while the underlying metal conductor reflects laser energy—eliminating the risk of wire damage, regardless of wire size. Laser stripping works with wires and cables of any shape (round, non-round, flat ribbon) and supports various stripping patterns, including end stripping, window stripping, slitting, and full-area ablation.

Compared to mechanical stripping, it requires no blade replacement or consumables, offering low maintenance and user-friendly operation. As medical devices become smaller and more sophisticated, laser wire stripping remains the preferred solution for meeting the industry’s demand for high-quality, complex wiring systems.

Future Trends of Laser Technology

As a cornerstone of Industry 4.0, laser technology continues to evolve through ongoing research worldwide. For example, the U.S. National Institute of Standards and Technology (NIST) has developed a laser with a pulse speed 100x faster than traditional ultrafast lasers (with pulse durations in the trillionth-of-a-second range). German scientists are experimenting with integrating micro-lasers directly into silicon chips to boost processing speeds.

Another promising area is the development of AI-powered "smart lasers" that can "recognize" materials being processed and determine when processing is complete.

As more companies embrace Industry 4.0—integrating AI, sensor technology, and additive manufacturing—lasers will play an increasingly pivotal role in modern manufacturing, unlocking new applications and possibilities.