Laser has become an indispensable tool in modern manufacturing. Especially driven by the development of additive manufacturing and Industry 4.0, it empowers engineers to create products with more complex features and strict tolerance requirements.

Laser processing can produce intricate structures that are difficult or even impossible for traditional equipment to achieve.

Moreover, it offers a clean processing experience—free from burrs or thermal effects on surrounding materials—eliminating the need for secondary finishing. As medical device manufacturers develop smaller, more advanced products, laser technology is increasingly becoming their preferred manufacturing solution.

The following are the top four of the seven core applications:

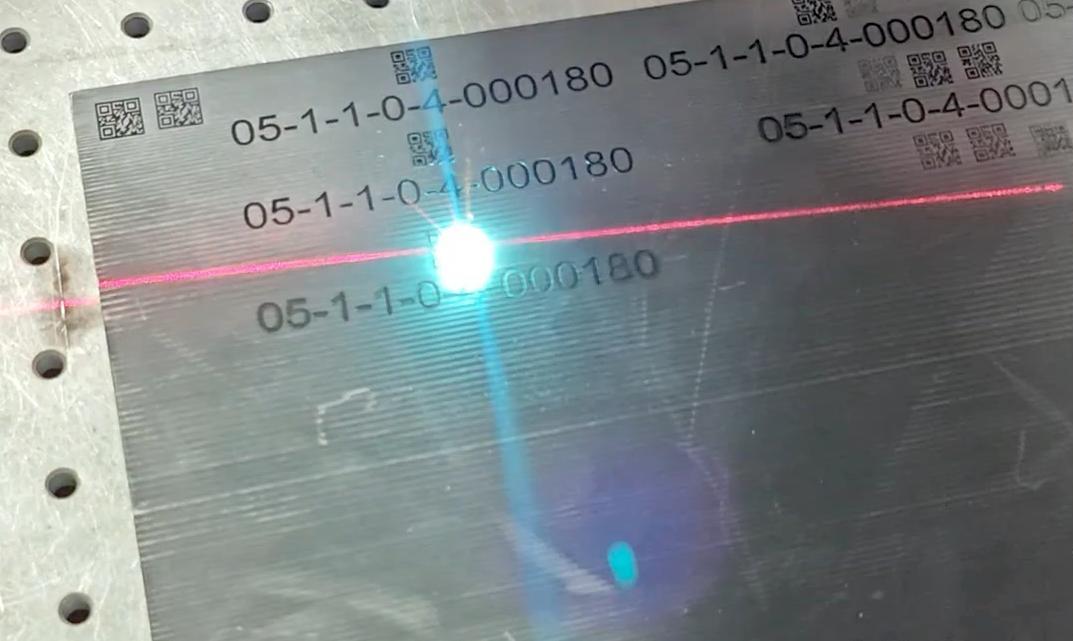

1. Laser Marking

Laser marking excels at printing Unique Identification (UID) codes on products and components, enabling easy traceability during recalls.

For medical devices, the marks are highly durable and can withstand repeated sterilization. Beyond UIDs, laser marking can also encode readable information, barcodes, batch/lot codes, and even design histories on parts with flat or curved surfaces.

Today, laser marking is widely adopted across industries such as automotive, aerospace, medical devices, electronics, and packaging. It has also expanded into areas like greeting cards, advertising, and stationery. In food and cosmetics packaging, laser marking not only enhances product aesthetics but also helps brands stand out from competitors.

Driven by the growing demand for precise, permanent marking solutions, technologies like fiber laser marking and CO₂ laser marking continue to evolve. However, the industry faces challenges such as reliance on third-party suppliers, which can lead to quality issues and delivery delays.

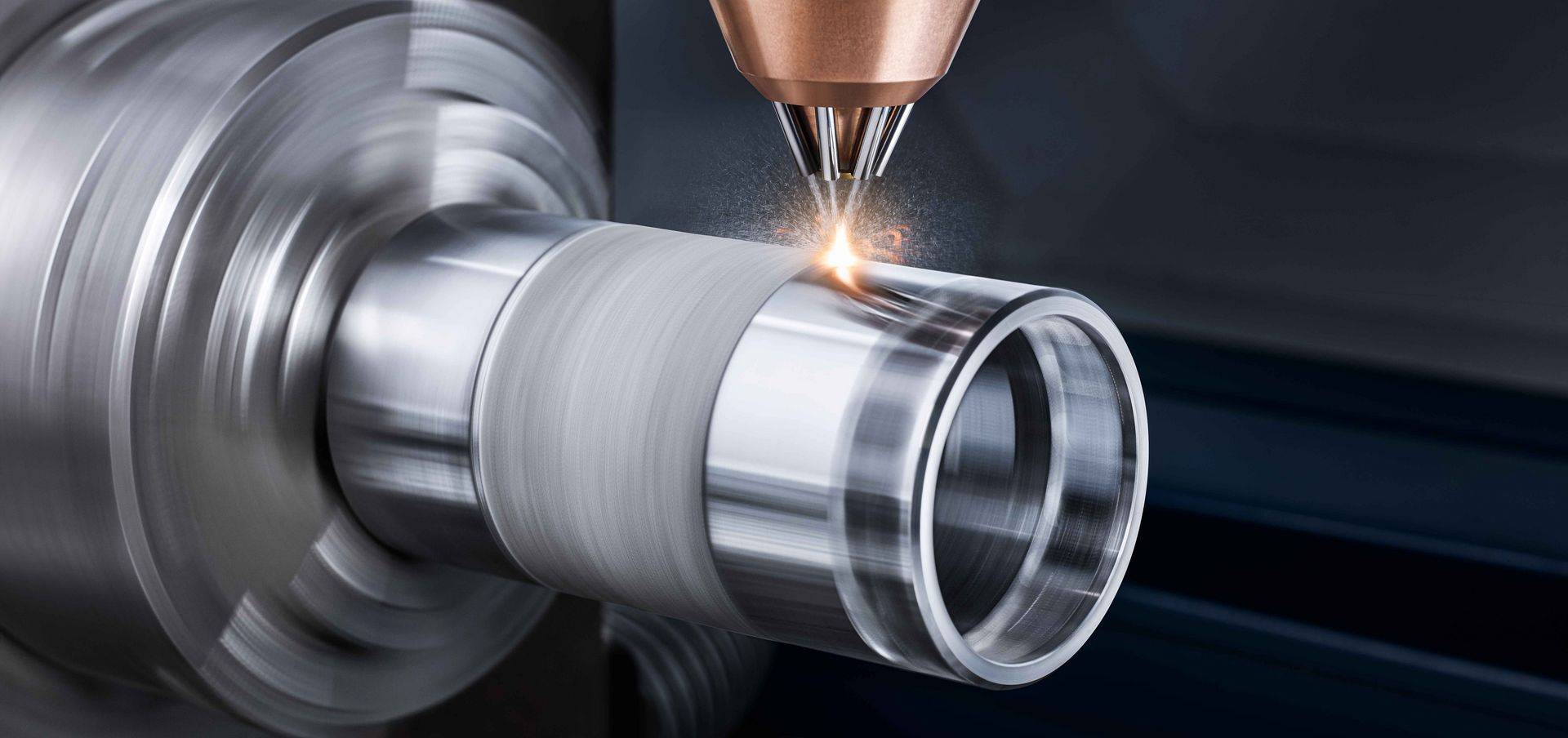

2. Surface Texturing

Laser surface texturing creates microstructured patterns or textures on workpiece surfaces by removing material through pulsed laser beams, forming pits that achieve specific roughness levels.

This process effectively improves key performance metrics such as wear resistance, grip, optical properties, and load-bearing capacity. In the field of medical implants, laser-induced surface roughness promotes faster integration and fixation with new tissues or bones.

The technology utilizes pulsed fiber lasers, and adjustable parameters—including laser power, pulse repetition rate (PRR), scanner speed, and lens focal length—allow for customized roughness levels to meet diverse needs.

Key advantages include high processing precision, no need to mask other surfaces, excellent process repeatability, no requirement for abrasive media, one-step production of multiple textures, and low operation and maintenance costs. With advancements in laser surface treatment technology, surface texturing is gaining broader adoption across various sectors.

3. Laser Ablation

Laser ablation is a "subtractive" manufacturing method that precisely vaporizes materials using laser beams. Parameters such as pulse duration, wavelength, and intensity can be tailored to different materials.

As a non-contact process, it does not alter the material’s inherent structure or damage the surface due to wear or heat, making it ideal for processing sensitive materials like nanomaterials and superconductors.

The rising demand for miniaturized electronic components and the widespread use of laser technology in microelectronics manufacturing are driving the growth of the laser ablation systems market.

Additionally, innovations such as ultrafast lasers and improved beam quality have enhanced the precision and efficiency of material removal.

Laser ablation is already applied in medical device manufacturing, semiconductor production, and nanotechnology research. However, strict safety regulations and environmental concerns pose challenges to market expansion.

4. Laser Drilling

Laser drilling delivers exceptional precision, enabling the creation of micron-scale holes in materials such as metals, polymers, and ceramics. Many modern products requiring tiny, complex features rely exclusively on laser drilling. It can produce intricate microstructures through methods like direct writing, percussion drilling, and mask projection—all without thermal effects or material damage.

Laser drilling’s popularity stems from its high repeatability, accuracy, flexibility, and cost-effectiveness. Compared to traditional mechanical punching, it eliminates the need for expensive stamping dies, reducing costs for prototyping or short-run production. It also features no wear-prone or breakable parts, allowing easy processing of high-strength materials.

Unlike mechanical punching, which limits hole diameter to roughly 1.0–1.5 times the material thickness, laser drilling offers unparalleled flexibility in hole shape and size.

Key factors influencing drilling quality include laser pulse energy, pulse width, defocus distance, PRR, and material properties.

The next issue will continue to introduce three other core applications: laser cutting, laser welding, and laser wire stripping.