In the ever-changing modern manufacturing industry, technological innovation is the core driving force for the development of the industry. Among many high-tech equipment, laser cutting machines, with their unique advantages of high precision, high efficiency and high flexibility, have become an indispensable processing tool in many fields.

They have not only reshaped the traditional manufacturing process, but also played a vital role in promoting the transformation of the manufacturing industry towards intelligence and greenness.

Let’s explore how laser cutting machines work, their advantages, and why they’re crucial.

1. Working principle and technical advantages of laser cutting machine

Are you curious about how laser cutting machines achieve such precision? Let me break it down.

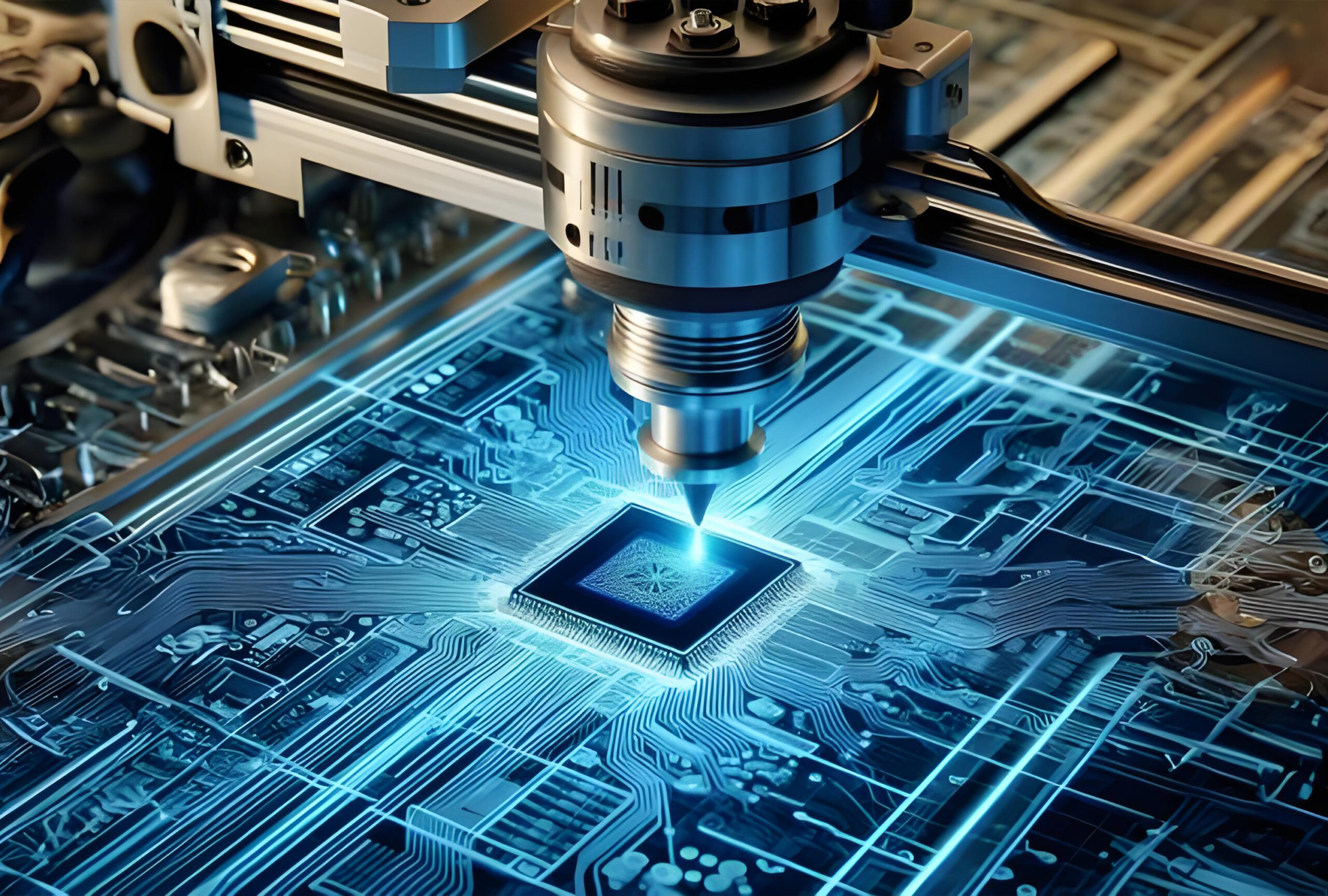

The laser cutting machine uses a high-power density laser beam as a "tool". Through precise computer control, the laser is focused on the surface of the material, causing the material to melt, vaporize, and even reach the ignition point quickly, thereby achieving non-contact cutting operations.

This process does not require traditional mechanical tools, avoiding wear and replacement costs. At the same time, the extremely small diameter of the laser beam ensures extremely high cutting accuracy and edge quality.

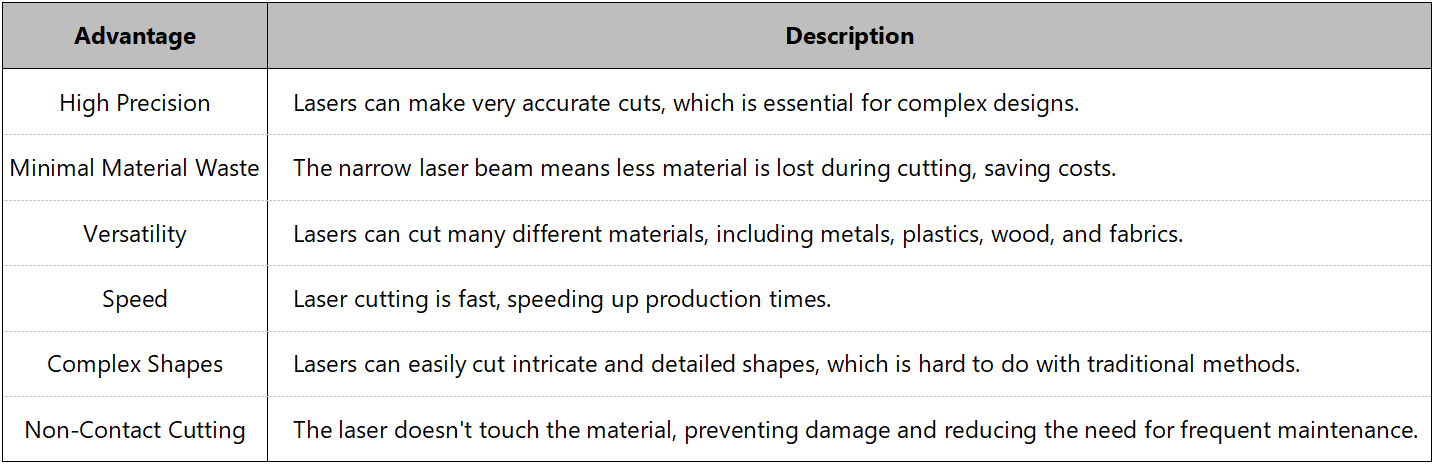

Here’s a quick look at some of the key technical advantages:

I remember when I first saw a laser cutting machine in action. I was amazed by how quickly and accurately it cut through a thick sheet of metal. The cuts were so clean that no further finishing was needed. It was a game-changer for the company.

2. Application value of laser cutting machine in manufacturing

Have you ever wondered how much laser cutting machines can improve manufacturing? They’re not just for making fancy cuts; they can seriously boost efficiency and quality.

Laser cutting machines enhance productivity, reduce costs, improve product quality, and offer flexibility in design and production.

Promote industrial upgrading: The application of laser cutting technology has promoted the transformation of manufacturing from labor-intensive to technology-intensive, and increased the added value of the overall industrial chain.

Optimize production processes: The automated and intelligent laser cutting system can seamlessly connect with other production equipment, realize the automated integration of production lines, reduce manual intervention, and improve production efficiency and quality control.

Promote green manufacturing: The laser cutting process produces almost no debris and pollutants, and the energy consumption is relatively low, which is in line with the current green and sustainable development trend of the manufacturing industry.

Inspire innovative design: The high precision and flexibility of laser cutting provide designers with greater creative space, making products with complex structures possible, and promoting the development of innovative product design.

I once worked with a client who was struggling to produce complex parts using traditional methods. After investing in a laser cutting machine, they saw a significant improvement in both the speed and quality of their production. Their costs went down, and their customer satisfaction went up.

3. Future Trends in Laser Cutting Machine Technology

Are you thinking about what’s next for laser cutting machines? The future looks bright with advancements that promise even greater efficiency and capabilities.

Future trends include advancements in fiber laser technology, automation, integration with AI, and new applications in various industries.

One of the main trends is the development of more powerful and efficient fiber lasers. Fiber lasers offer better beam quality, higher cutting speeds, and lower energy consumption compared to traditional CO2 lasers. This means faster production and lower operating costs.

Automation is another key trend. Laser cutting machines are increasingly being integrated with robotic systems to automate material handling and part removal. This reduces the need for manual labor and increases overall efficiency.

The integration of artificial intelligence (AI) is also on the rise. AI can be used to optimize cutting parameters, detect defects, and predict maintenance needs, further improving productivity and reducing downtime.

In terms of applications, laser cutting machines are finding new uses in various industries, including aerospace, automotive, electronics, and medical device manufacturing. As technology advances, we can expect to see even more innovative applications in the future.

I believe that laser cutting machines will play an even bigger role in manufacturing. Their ability to deliver precision, efficiency, and flexibility makes them essential for companies looking to stay competitive.

Conclusion

In short, laser cutting machines have become an indispensable part of modern manufacturing with their incomparable technical advantages, and play a vital role in promoting the transformation and upgrading of the manufacturing industry.

With the continuous evolution of technology and the continuous expansion of application fields, laser cutting machines will continue to lead the manufacturing industry towards a more efficient, smarter and more environmentally friendly future.