In the industrial sector, common traditional cleaning methods include chemical cleaning, dry ice cleaning, sandblasting, mechanical grinding, and ultrasonic cleaning.

As environmental protection and safety awareness continue to rise, the market is demanding higher cleaning performance and efficiency. Laser cleaning technology stands out with its core advantages of being more eco-friendly, cost-effective, and practical, making it a sought-after new-generation industrial cleaning solution.

1. Principle of Laser Cleaning

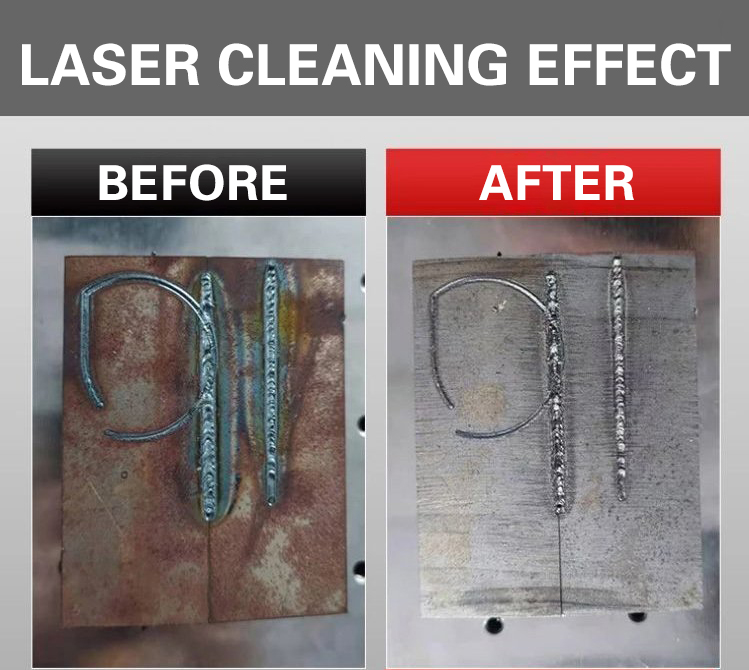

The core principle of laser cleaning is: irradiating a high-energy-density laser beam on the surface of the workpiece, causing the dirt, oxide layer, plating layer or coating on the surface to instantly melt, ablate, evaporate or peel off after being heated, thereby achieving the cleaning of the workpiece surface without damaging the base material.

As a new generation of industrial cleaning technology, laser cleaning is undoubtedly an ideal choice for efficient cleaning treatment.

2. Core Advantages of Laser Cleaning Machine

Compared with traditional derusting and cleaning methods, the laser cleaning machine, as a new generation of intelligent cleaning equipment, can accurately remove stains without damaging the surface metal. It has multiple advantages such as convenient operation, easy integration, high cleanliness and fast cleaning speed, which are specifically reflected in the following three aspects:

· More Advanced Cleaning Solution

It can realize local precise derusting, accurately clean the cleaning dead corners of specified positions and specific sizes, with a wide range of application scenarios; adopt non-contact cleaning mode, no damage to the base material, no pollution, and no additional subsequent treatment after cleaning.

· More Intelligent Operation Experience

Deeply integrated with numerical control technology, it can realize automatic target scanning, long-term continuous operation and long-distance remote control cleaning, easily adapt to the automated production process, and facilitate the realization of full-process automatic control.

· More Efficient Cost Control

It produces minimal thermal and mechanical loads on the base material, realizing non-destructive cleaning, effectively reducing subsequent repair costs and improving product quality; the equipment is convenient and lightweight, can be moved freely, has high safety and reliability, and will not endanger the health of operators.

3. Applicable Industries

The laser cleaning equipment produced by Baokun Laser, relying on its excellent work efficiency, has been widely used in aerospace, auto parts, lighting and mold manufacturing, optoelectronic communication devices, medical equipment, electronic components, household appliances, hardware structural parts and other industries.