Laser cutting machines play an increasingly important role in modern industry. Their high precision and high efficiency make them widely used in many fields.

The following are the twelve advantages of laser cutting machines. Let’s take a look!

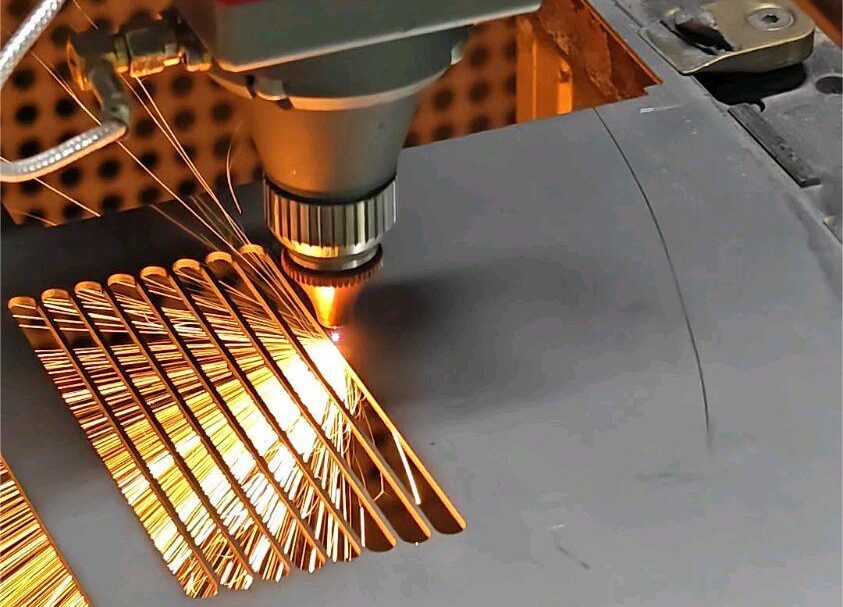

1. High-precision cutting

The positioning accuracy of the laser cutting machine is as high as 0.01mm, and the repeated positioning accuracy is also 0.01mm, ensuring the accuracy of cutting.

Laser cutting machines offer exceptional accuracy, allowing for intricate designs and tight tolerances that other methods can’t match.

2. Narrow slit

The laser beam is focused into a very small light spot, which makes the power density at the focus extremely high. The material is quickly heated to the degree of vaporization, forming a narrow slit. The incision width is usually between 0.10-0.20mm.

The narrow cutting slit of laser cutting machines minimizes material waste, leading to cost savings and more efficient use of resources.

3. Smooth cutting surface

The cutting surface is burr-free, and the roughness of the incision surface is generally controlled within Ra6.5, ensuring the cutting quality.

Laser cutting machines produce a smooth cutting surface, reducing the need for secondary finishing processes and saving time and money.

4. Fast cutting

The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than traditional wire cutting.

Laser cutting machines offer high cutting speeds, significantly reducing production time and increasing overall efficiency.

5. High-quality cutting

The non-contact cutting method reduces the heat effect, the cutting edge is less affected by heat, there is no thermal deformation of the workpiece, and the cutting seam does not require secondary processing.

Laser cutting machines provide consistent, high-quality cuts, ensuring that each part meets the required specifications and standards.

6. No damage to the workpiece

The laser cutting head does not contact the surface of the material, ensuring that the workpiece is not scratched.

Laser cutting is a non-contact process, which means there is no physical contact between the cutting tool and the material, preventing damage and deformation.

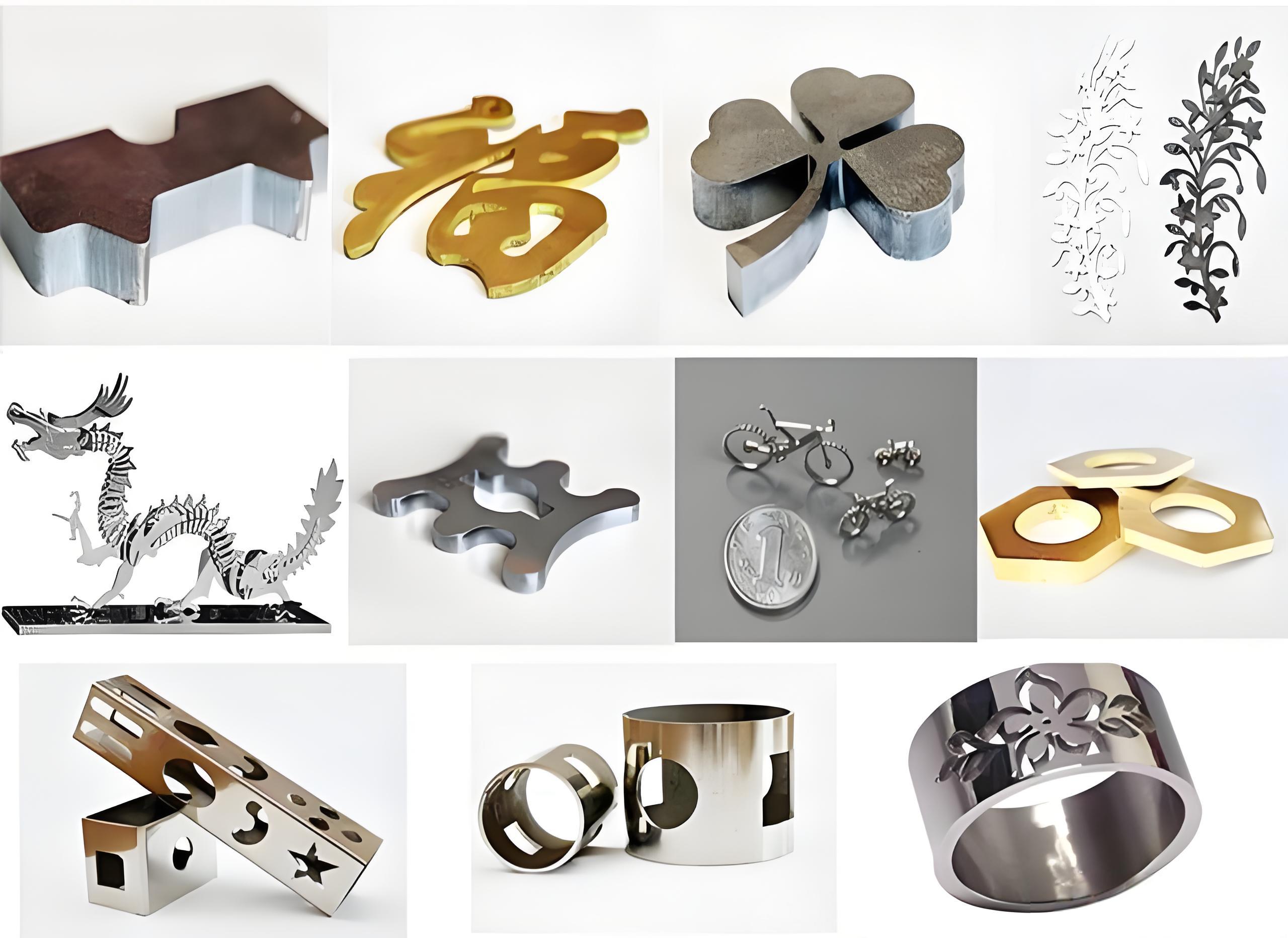

7. Adapt to various shapes

The laser processing is flexible and can process any graphics, including pipes and other special-shaped materials.

Laser cutting machines can easily adapt to various shapes and designs, allowing for the production of complex and customized parts.

8. Applicable to a variety of materials

Applicable to a variety of materials such as metal, plastic, wood, PVC, leather, textiles, plexiglass, etc.

Laser cutting machines can cut a wide variety of materials, making them a versatile tool for many industries.

9. Save mold investment

Laser processing does not require molds, saving mold investment, mold replacement time and cost, especially suitable for the processing of large products.

Laser cutting can eliminate the need for expensive molds and dies, reducing tooling costs and lead times, especially for small to medium production runs.

10. Save materials

Through computer programming, the utilization rate of materials can be maximized.

Laser cutting minimizes material waste due to its precision and narrow cutting slit, leading to cost savings and more sustainable manufacturing practices.

11. Fast sample delivery

After the product drawing is formed, laser processing can be carried out immediately, shortening the sample delivery time.

Laser cutting enables fast sample delivery, accelerating the prototyping process and allowing for quicker design iterations and product development.

12. Safety and environmental protection

Laser processing has less waste, low noise, clean, safe, pollution-free, and improves the working environment.

Laser cutting is a safe and environmentally friendly manufacturing process, producing minimal waste and emissions compared to traditional methods.

Conclusion

Laser cutting machines offer many advantages, including precision, speed, and versatility. These benefits make them a valuable tool for businesses in many industries.