There are significant differences between CO₂ laser cutting machine and fiber laser cutting machine in many aspects, including light source, processing material, production cost, maintenance cost, cutting efficiency and applicable scenarios.

1. Light Source and Processing Material

The CO₂ laser cutting machine uses CO₂ gas as the laser medium and generates a high-energy laser beam through electrical excitation. Its beam wavelength is 10.64um, which is suitable for cutting non-metallic materials such as wood, plastic, etc., and is also suitable for metal materials.

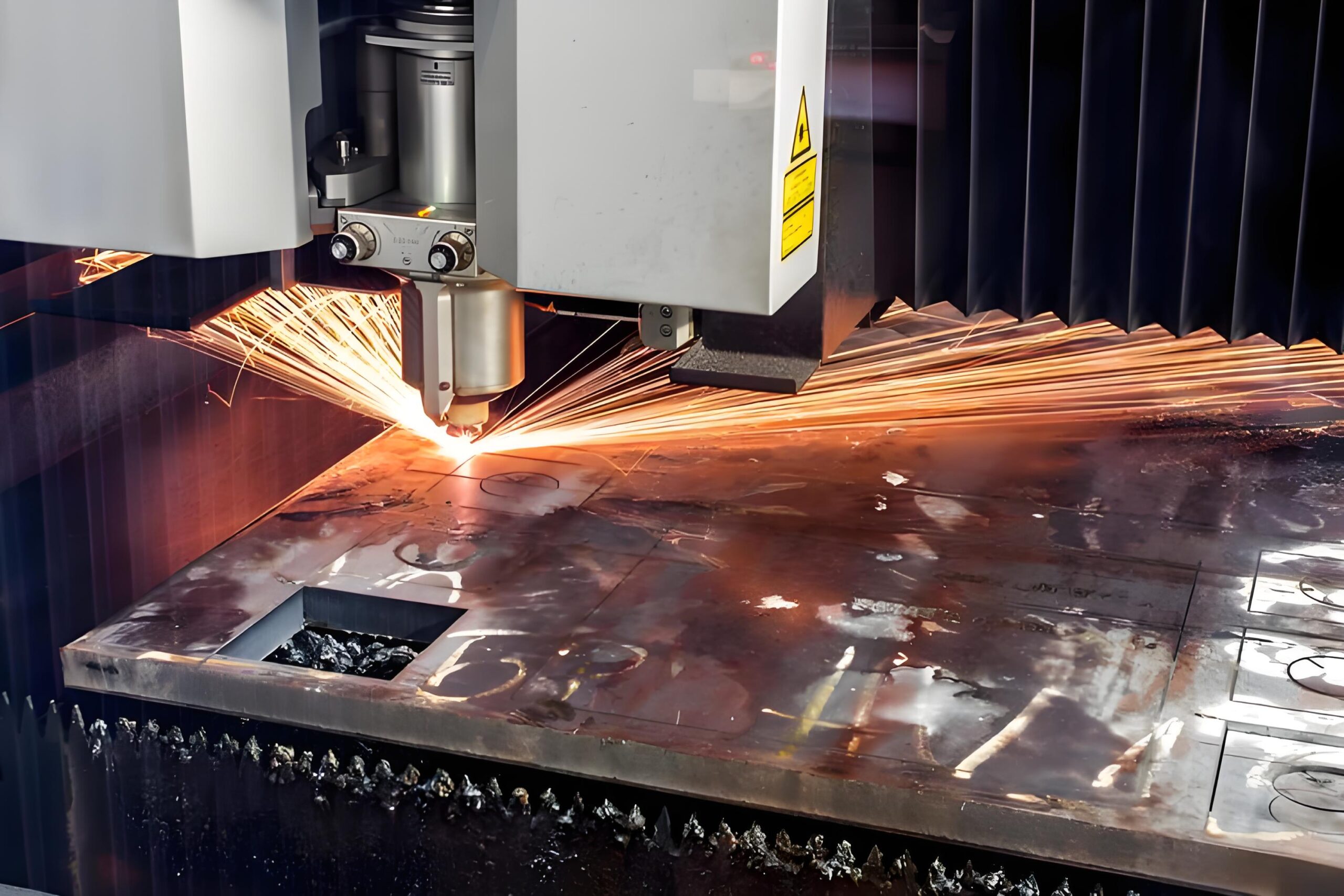

The fiber laser cutting machine uses optical fiber as the transmission medium and generates a laser beam through diode pumping. Its beam wavelength is 1.064μm, which is more suitable for cutting metal materials, especially thin to medium thickness metal sheets.

2. Production Cost and Maintenance Cost

The initial investment of the CO₂ laser cutting machine is relatively low, but its photoelectric conversion rate is only 8% to 10%, and the gas and lens need to be replaced regularly, and the maintenance cost is high. In addition, CO₂ lasers consume a lot of energy and have a complex maintenance process, requiring regular cleaning and maintenance of mirrors and resonant cavities.

The initial investment of fiber laser cutting machines is high, but their photoelectric conversion efficiency can reach 25% to 30%, and their energy efficiency is increased to more than 86%, significantly reducing energy consumption and operating costs. Fiber lasers do not require frequent replacement of gases and lenses, have low maintenance costs, and are more environmentally friendly and durable.

3. Cutting Efficiency and Applicable Scenarios

CO₂ laser cutting machines are suitable for large-area cutting and engraving, especially when thick plates need to be cut, and are suitable for billboard production, furniture manufacturing and other fields. However, its beam diffusion is large, not suitable for large-scale processing, and the processing speed of thick plates is slow.

Fiber laser cutting machines are known for their high efficiency and high precision, suitable for high-precision and high-efficiency metal sheet cutting, and are widely used in automotive manufacturing, aerospace and other fields. The fiber laser cutting machine has a high laser beam density and high intensity, can quickly cut thinner materials, and performs well in cutting medium-thick materials.

Conclusion

In summary, CO₂ laser cutting machines and fiber laser cutting machines have significant differences in many aspects. Fiber laser cutting machines have gradually become the mainstream choice in the market with their high efficiency, environmental protection and low maintenance cost. However, it is still crucial to choose the right type of laser cutting machine according to specific needs and material types. How to choose is often a difficult problem, and Baokun will provide you with a full range of laser cutting equipment consulting services and tailor the most suitable laser processing solutions for you.