Introduction

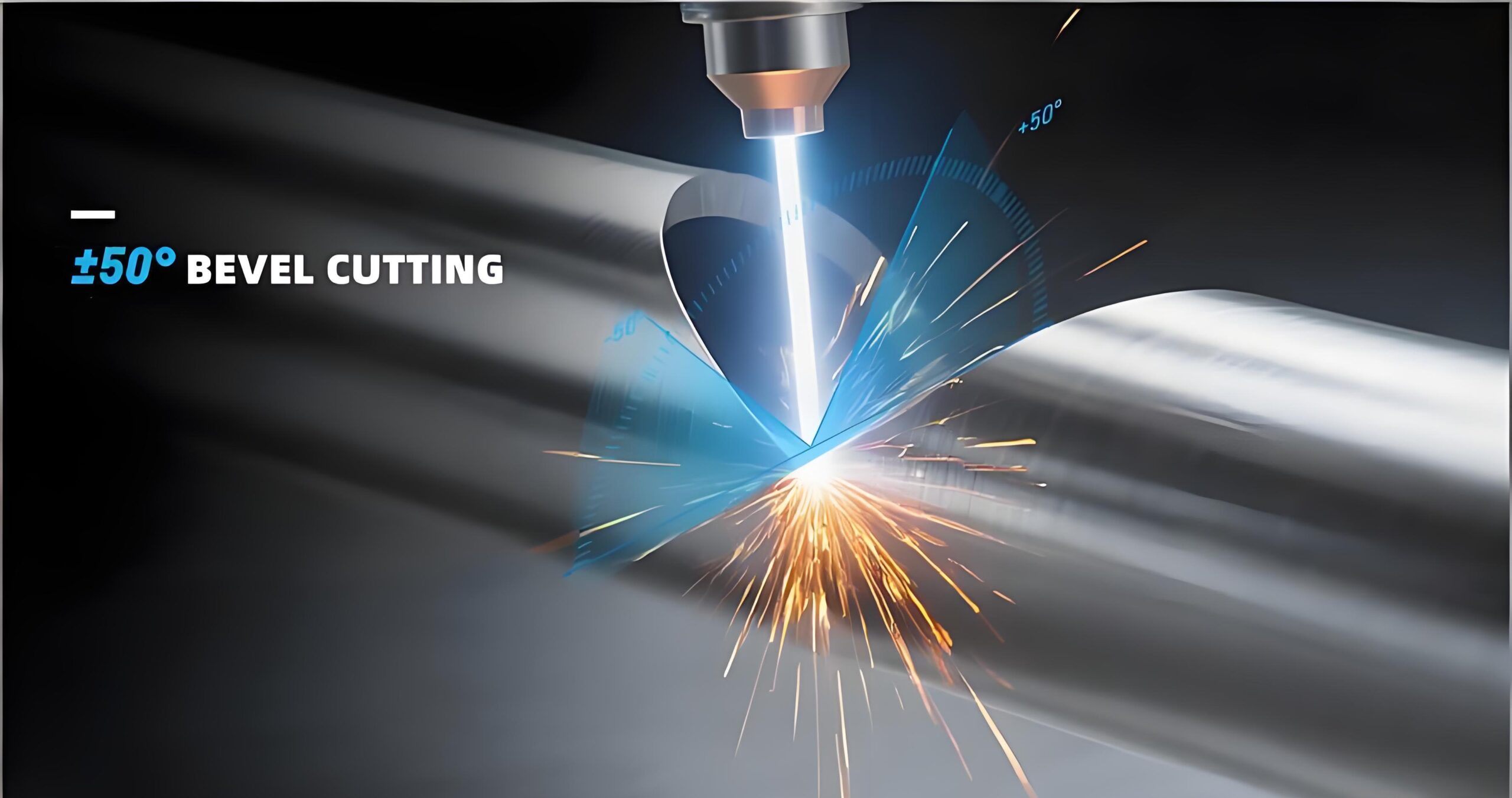

In pipe welding, structural frame joining and similar fields, smooth angled pipe joints are primarily achieved through bevel cutting. Traditional straight-cut pipe welding is plagued by large gaps, low strength and poor aesthetics. The bevel laser pipe cutting machine effectively addresses this pain point, serving as core equipment for precision machining.

I. Bevel Cutting: Beyond Simple Angled Cuts

Bevel cutting is a process that creates angled surfaces or notches on metal pipes and sheets, with its core value lying in optimizing welding performance. It expands the weld contact area, enabling full solder filling to significantly enhance joint strength and sealing. Additionally, it ensures precise pipe alignment, reducing the time and costs associated with subsequent grinding and finishing.

In contrast, straight cutting provides a limited contact area, insufficient weld firmness and higher consumable consumption, failing to meet the demands of complex structural machining.

II. Core Advantages of Bevel Laser Pipe Cutting Machines

Compared to traditional semi-manual and semi-mechanical bevel processing (sawing/flame cutting + manual grinding), bevel laser pipe cutting machines achieve dual breakthroughs in high precision and efficiency. Integrated with multi-axis pipe rotation technology, they complete blanking, beveling and drilling in one continuous operation, drastically streamlining workflows.

Precision & Efficiency

Processing precision is elevated from the traditional millimeter level to 0.1mm (wire level). The cut surface is smooth and burr-free, eliminating the need for rework. With no heat-affected zone deformation, processing efficiency is multiplied.

Moreover, laser non-contact operation avoids extrusion deformation and scratches on thin-walled pipes, while eliminating concerns about tool wear. Computer programming enables flexible switching of pipe shapes and bevel angles, adapting to small-batch, multi-variety complex machining needs.

III. Technical Challenges of Bevel Cutting

Bevel cutting poses higher technical barriers than straight cutting, requiring a multi-dimensional high-precision linkage system. Unlike straight cutting—where pipes rotate at a constant speed and laser heads move simply—bevel cutting demands that laser heads move at set angles in 3D space, synchronizing precisely with pipe rotation. This typically relies on 5-axis or 6-axis linkage systems, with strict requirements for motion trajectory algorithms.

Angle adjustments also necessitate real-time tuning of laser parameters (focus, power, air pressure), while imposing rigorous standards on equipment mechanical precision, calibration and the underlying logic of the CNC system. Thus, stable high-precision bevel cutting capability is a key indicator of a manufacturer’s technical strength.

IV. Scenarios for Bevel Laser Pipe Cutting Machines

Equipment with stable, high-quality bevel cutting capabilities comes at a premium and is not essential for all enterprises. However, it is a worthwhile investment in the following scenarios:

-

Industries requiring high welding quality and assembly precision (e.g., medical devices, pressure vessels, aerospace), helping products penetrate mid-to-high-end markets.

-

Processing high-value materials (stainless steel, aluminum alloy) or multi-angle intersecting structures (trusses, frames), minimizing losses caused by machining errors.

-

Small-batch, multi-variety production, leveraging fast program switching to support flexible manufacturing.

-

Enterprises pursuing digitalized, standardized machining workflows to reduce reliance on manual experience and stabilize product quality.