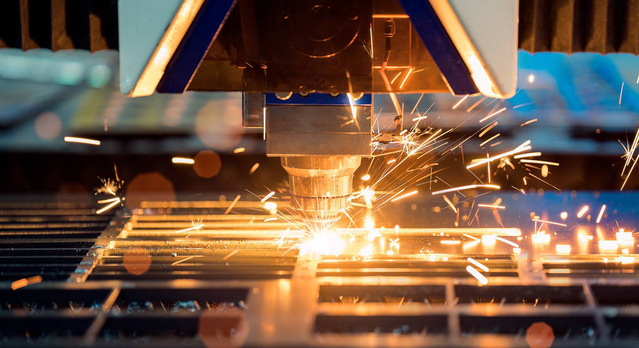

The machining quality of a fiber laser cutting machine hinges on the precise control of four core parameters: cutting speed, nozzle configuration, focus position and shielding gas pressure.

Below is a professional and practical optimization method for reference:

1. Cutting Speed: Match the Sheet for High Efficiency

Cutting speed should be adapted to the characteristics of the sheet instead of blindly pursuing high speed:

- Optimal speed: Sparks spread evenly, the cutting surface is smooth, and no dross remains on the lower part of the sheet.

- Too fast: Sparks tilt, easy to cause incomplete cutting or diagonal lines on the section, with increased dross.

- Too slow: Sparks cluster together, the cutting surface becomes rough, the kerf widens, and over-melting occurs.

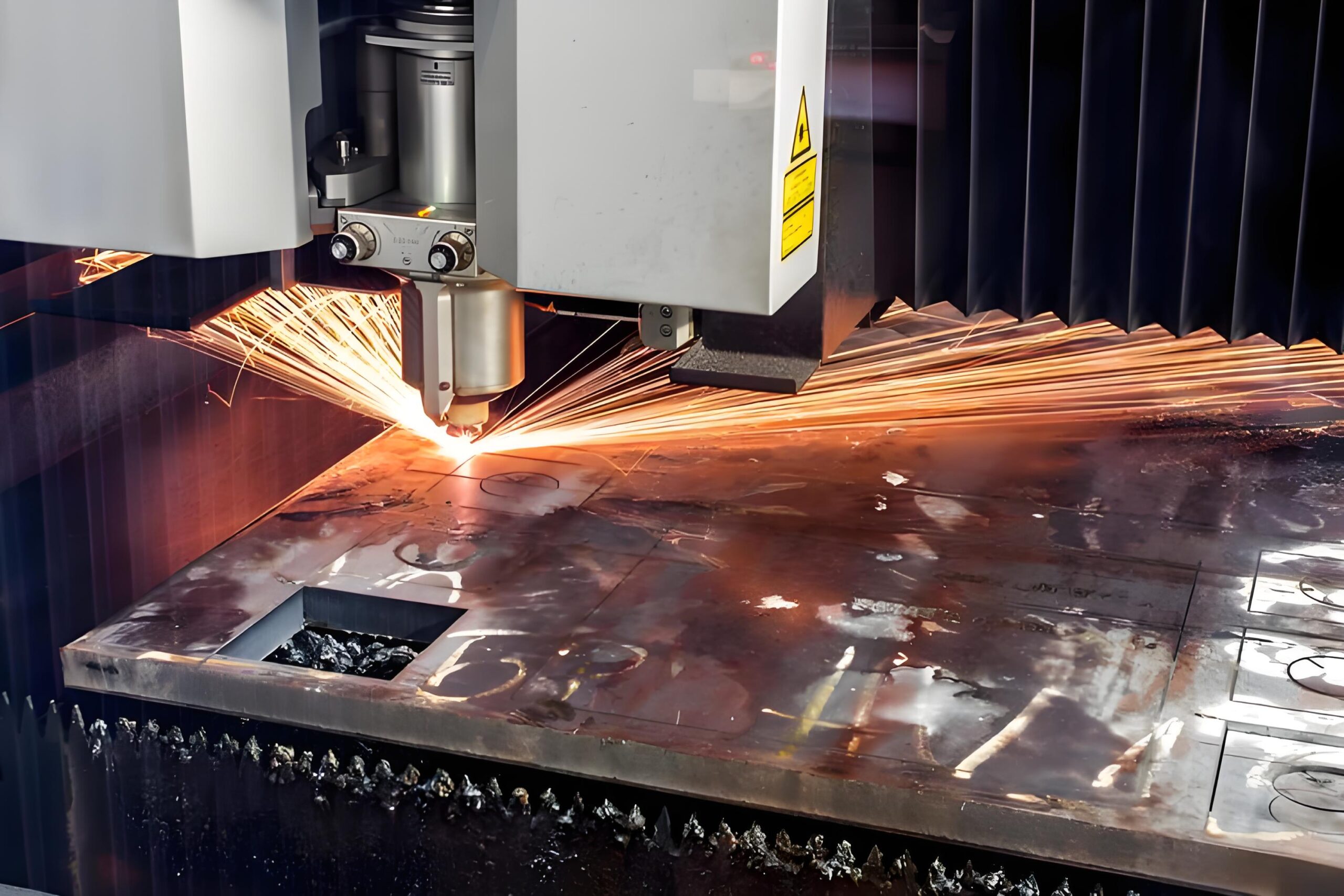

2. Nozzle & Nozzle Height: Right Selection + Precise Distance Control is Key

The type, aperture and height of the nozzle directly affect gas protection and cutting results:

Nozzle Selection

- Use small-aperture nozzles for thin sheets and large-aperture nozzles for thick sheets.

- Match single-layer nozzles with nitrogen (for fusion cutting of stainless steel, aluminum plates, etc.) and double-layer nozzles with oxygen (for oxidative cutting of carbon steel, etc.).

Height Control

- Set the height to 0.3-0.8mm for regular cutting: too low may cause collision with the workpiece, while too high will reduce gas pressure.

- Raise the nozzle appropriately during piercing to avoid lens contamination by molten dross.

3. Focus Position: Precisely Locate According to Sheet Thickness

Focus position determines kerf shape and section quality, select the position based on sheet thickness:

- Zero focal length: Focus on the workpiece surface, suitable for thin sheets.

- Negative focal length: Focus at 1/2-2/3 below the workpiece surface, with a large smooth surface area and a slightly wider kerf.

- Positive focal length: Focus on the upper surface of the workpiece, suitable for thick carbon steel sheets to avoid overburning.

4. Shielding Gas Pressure: Moderate Pressure Balances Quality and Efficiency

Adjust the auxiliary gas pressure according to the material and cutting speed:

- Insufficient pressure: Unable to remove dross, leading to incomplete cutting and low efficiency; higher pressure is required for high-speed cutting of thin sheets to prevent dross.

- Excessive pressure: Excessively fast gas flow interferes with focusing and enhances the cooling effect, resulting in rough cutting surfaces, widened kerfs and even reduced cutting speed; lower the pressure appropriately for thick sheets or low-speed cutting.

Summary

In conclusion, the four core parameters of fiber laser cutting are interrelated and mutually restrictive, and there is no universal "one-size-fits-all" setting.

By comprehensively adjusting these parameters and conducting small-batch tests before formal processing, you can effectively maximize the performance of the equipment.