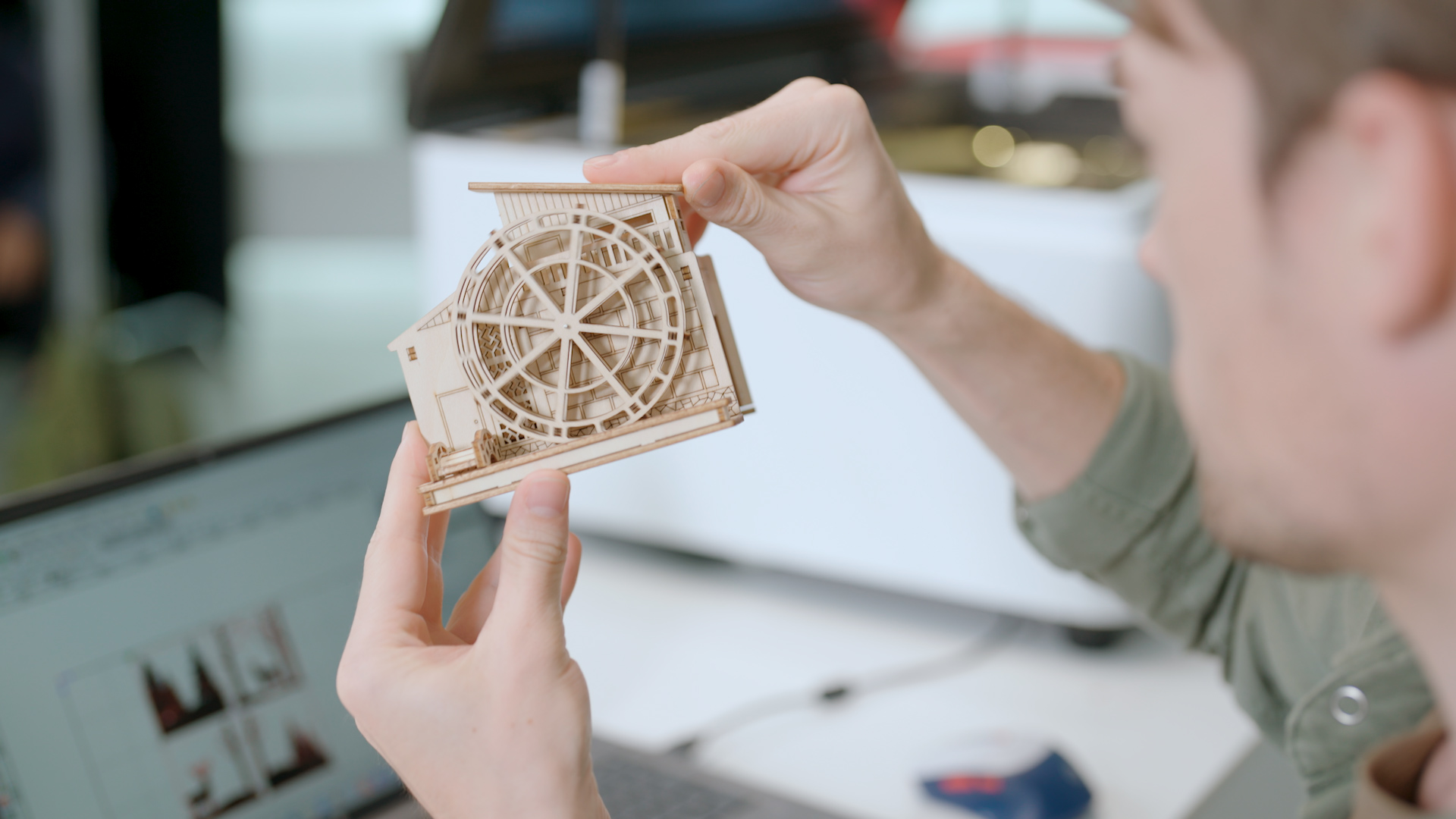

Small cultural and creative startup studios often struggle to balance unique design appeal with bulk production needs. Traditional manual work is slow, industrial equipment is too costly, and inconsistent quality harms brand credibility—laser cutters solve these pain points. Compact, affordable, and versatile, they let small studios scale efficiently without losing their creative edge.

Below’s a concise breakdown of their impact.

Core Challenges Small Studios Face in Bulk Production

- Slow manual work: Cutting/engraving materials (wood, acrylic, leather) by hand takes days for 50+ units, causing missed deadlines.

- Inconsistent quality: Manual processing leads to size/shape variations, undermining premium product value.

- High cost barriers: Industrial equipment ($50k+) is unaffordable, while low-quality tools fail to deliver professional results.

Advantages of Laser Cutters for Small Studios

1. Slash Production Time by 60-80%

Laser cutters automate repetitive tasks, turning days of work into hours:

- 100 wooden coasters: 2-3 hours (laser) vs. 2-3 days (manual).

- 50 engraved acrylic keychains: 45 minutes (laser) vs. 8+ hours (hand engraving).

- Unattended batch processing: Load material sheets and focus on design/customer service while the laser works.

2. Ensure Uniform Quality Across Every Unit

Consistency builds trust—laser cutters deliver precision manual work can’t match:

- ±0.03-0.05mm cutting accuracy ensures all products match your design.

- Smooth edges (e.g., flame-polished acrylic) and uniform engraving elevate perceived value.

- Reusable design files: Reproduce limited-edition runs or restock bestsellers infinitely.

3. Low Entry Cost & Multi-Material Versatility

Laser cutters fit small studio budgets and needs:

- Affordable equipment: $3k-$10k with ROI in 3-6 months.

- Multi-material compatibility: Cut/engrave wood, acrylic, leather, paper, felt, and thin metal—no need for separate tools.

- Low operating costs: ≈$0.50-$1 per hour in electricity; simple, low-cost maintenance.

Top 3 Product Categories for Laser Cutter Bulk Production

- Custom home decor: Wooden wall art, acrylic light boxes, engraved coasters (easy to scale for online/retail sales).

- Branded merchandise: Engraved keychains, leather phone cases, paper notebooks (ideal for corporate gifts/souvenirs).

- Traditional craft reproductions: Laser-cut paper cuttings (jianzhi), wooden lanterns, bamboo decor (preserve culture while scaling).

Final Takeaway

Laser cutters are game-changers for small studios—they automate production, ensure consistency, and lower cost barriers, letting you scale from "handmade" to "bulk professional" without losing creativity. Whether you’re fulfilling 50 or 500 orders, a laser cutter helps you meet demand, boost profits, and build a reputable brand.

For personalized advice on choosing the right laser cutter for your products, contact our team.