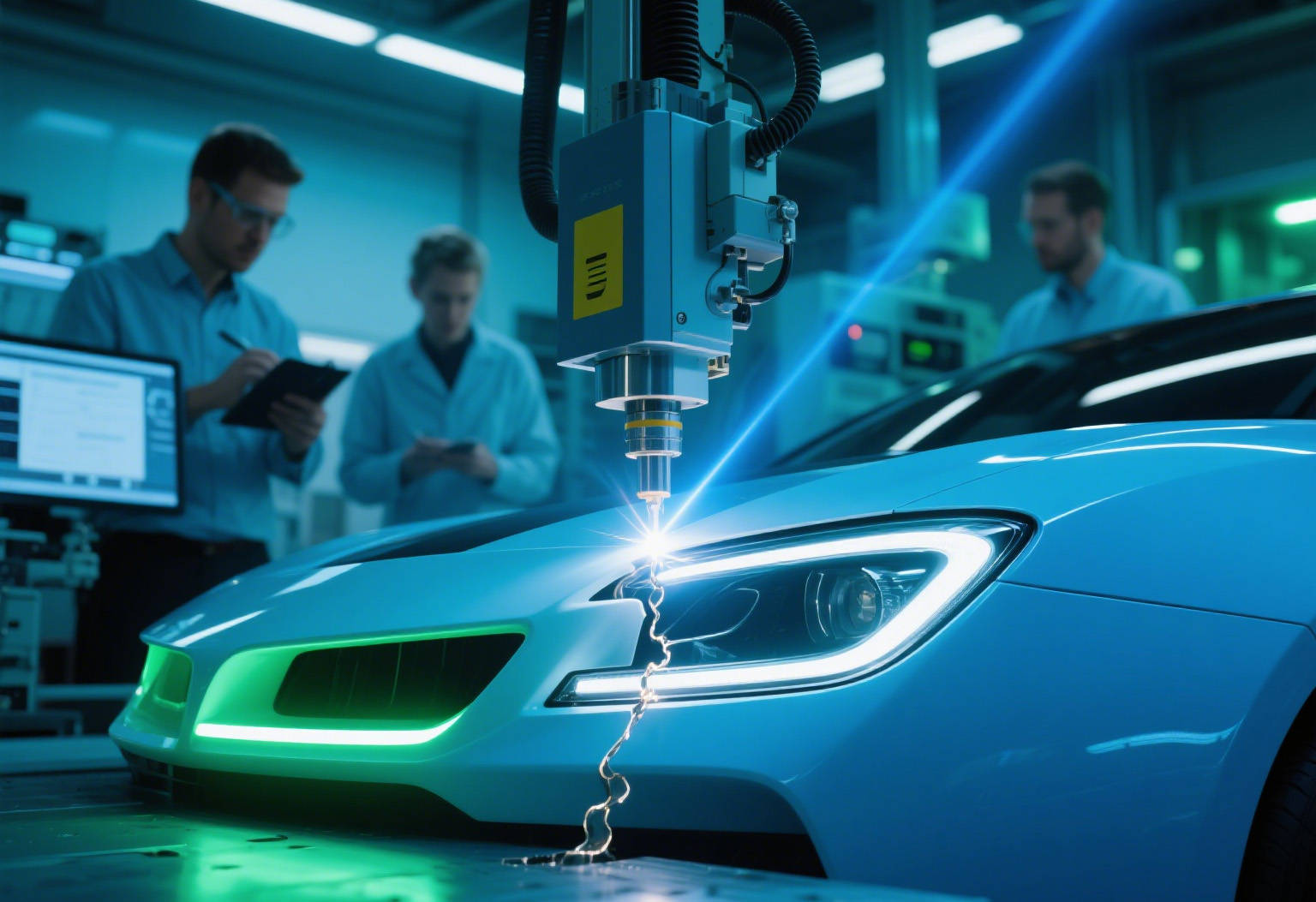

Automotive manufacturers are constantly balancing quality and cost—especially in component processing. Traditional methods like stamping, plasma, and waterjet cutting have long been standard, but they come with hidden expenses that eat into profits. Laser cutting has emerged as a smarter alternative.

Traditional Processes Lack Cost Efficiency

- High tooling costs: Stamping requires custom dies ($15,000–$80,000) that can’t be easily modified, making small-batch runs or design changes prohibitive.

- Material waste: Plasma/waterjet cutting has wider kerf (0.5–1.5mm), leading to 4–8% more material waste than laser cutting.

- Post-processing expenses: Rough edges and deformation from traditional cuts add 5–15 minutes of labor per component for deburring or straightening.

- Slow lead times: Stamping die production takes 4–8 weeks, and plasma/waterjet cutting is 30–50% slower for complex shapes.

Core Cost Advantages of Laser Cutting

1. Eliminate Tooling Costs & Enable Flexibility

Laser cutting is "tool-less", so no custom dies or fixtures are needed:

- Save $15,000–$80,000+ per component design by skipping upfront tooling.

- Adapt seamlessly to design changes (critical for EV prototypes or model updates) with no extra costs.

- Work for both high-volume (10,000+ units/month) and small-batch (100–500 units) runs.

2. Reduce Material Waste

Precision laser cutting minimizes raw material costs:

- Narrow kerf (0.1–0.3mm) allows tighter component nesting, cutting material usage by 3–6% (saves $1,500–$4,000/month for mid-sized facilities).

- High accuracy (±0.03–0.05mm) reduces scrap rates from 2–3% (traditional) to 0.5–1%.

3. Cut Post-Processing Labor

Laser cutting delivers near-ready-to-assemble components:

- Smooth, burr-free edges eliminate 80–90% of deburring/grinding, saving 5–12 minutes per component.

- Minimal thermal impact (heat-affected zone <0.1mm) avoids deformation and reworking.

Real-Example: EV Battery Tray Manufacturer

A mid-sized producer switched from stamping to 6kW fiber laser cutting, with verified results:

- Tooling costs: Reduced from $45,000 to $0.

- Material waste: Dropped from 7% to 2 ($3,200/month savings).

- Post-processing labor: Cut by 28% ($4,100/month savings).

- Total ROI: Achieved in 5.2 months, with $7,300/month ongoing savings.

Who Benefits Most?

Laser cutting is ideal for manufacturers producing:

- Complex components (chassis brackets, battery housings, exhaust parts).

- Small-to-medium batches or designs with frequent updates.

- High-precision parts requiring tight tolerances.

Final Takeaway

Laser cutting’s cost advantages is not just a technical upgrade, but a profitable choice for manufacturers adapting to EVs, customization, and faster time-to-market.

For personalized cost projections or advice on fitting laser cutting to your components, contact our technical support team.