The fiber laser cutting as a highly representative high-efficiency and precision processing equipment in modern manufacturing.Boasting outstanding advantages of high processing efficiency and cutting precision, it is widely applied in processing both metals and certain non-metallic materials.

I. Core Applicable Materials: Metals as the Primary Focus, Non-Metals as Supplementary

(I) Metal Materials: Core Processing Objects

Metals are the primary processing scope of fiber laser cutting machines, covering most common metals in industrial production. Each material features unique processing characteristics and application scenarios:

1. Stainless Steel (e.g., grades 304, 316L)

- Typical applications: Kitchen equipment, medical devices, architectural decoration, home appliance casings

- Processing advantages: Enables burr-free, heat-deformation-free precision cutting, especially suitable for thin plates (1-10mm) with no need for post-processing grinding

2. Carbon Steel/Alloy Steel (including ordinary carbon steel, low-alloy steel)

- Typical applications: Machinery manufacturing, auto parts, building structures, pipeline engineering

- Processing parameters: Medium-to-high power equipment (≥2000W) can easily cut medium-thick plates (5-25mm) with smooth, flat cutting surfaces that meet direct assembly requirements

3. Aluminum & Aluminum Alloys (e.g., grades 6061, 7075)

- Typical applications: Aerospace components, automotive lightweight parts, electronic heat dissipation devices

- Key notes: High laser reflectivity requires parameter adjustments (reduce cutting speed + increase laser power); ideal for thin plates (1-8mm); thick plates need higher-power equipment

4. Copper & Copper Alloys (e.g., red copper, brass)

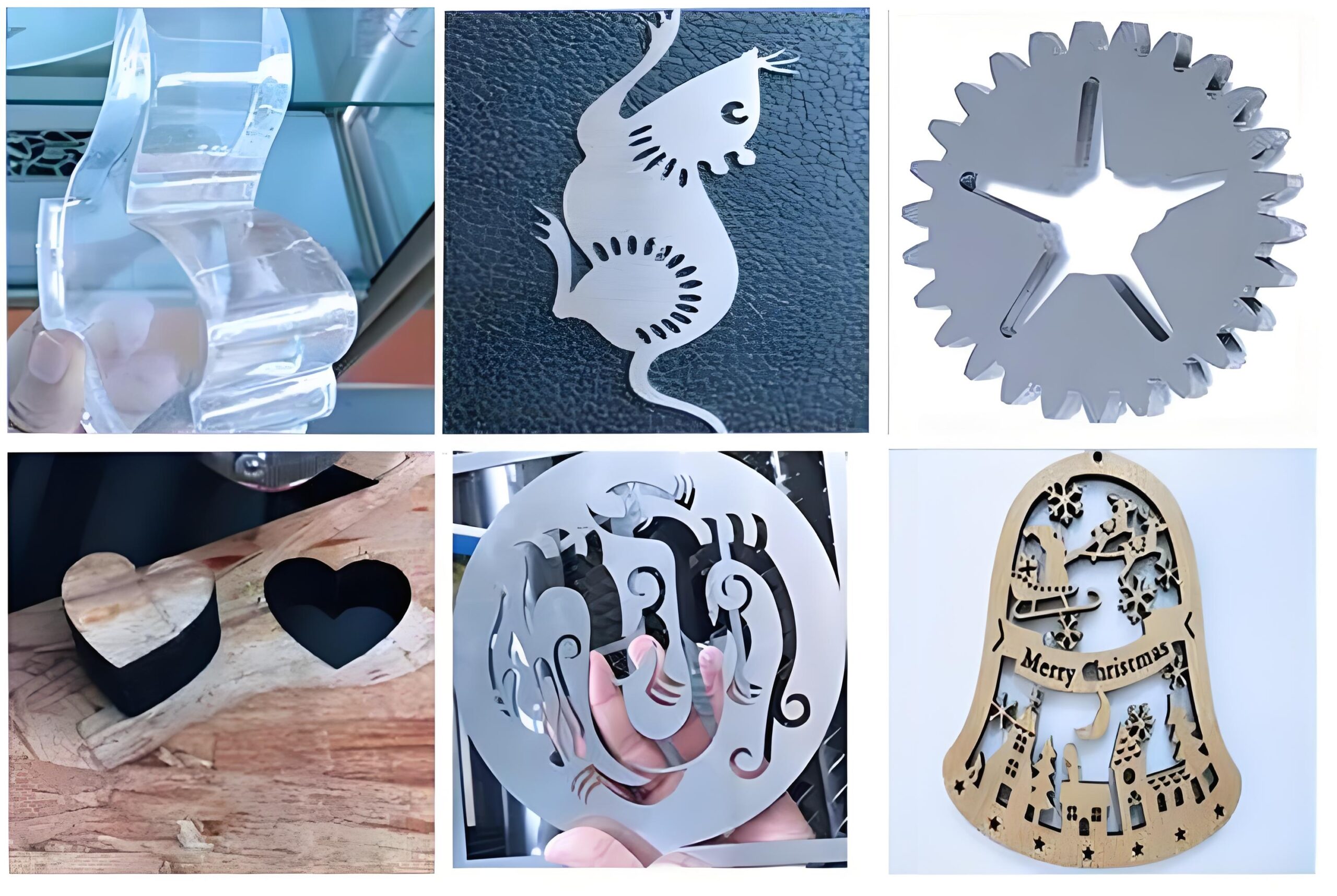

- Typical applications: Electronic components, pipeline systems, decorative crafts

- Key notes: Extremely high thermal conductivity demands strict heat input control to avoid slag; suitable for thin plates (1-5mm)

5. Titanium & Titanium Alloys (e.g., grade TC4)

- Typical applications: Aerospace parts, medical implants (e.g., artificial joints), chemical equipment

- Key notes: High chemical activity requires inert gas protection (e.g., argon) to prevent oxidation; handles thin-to-medium-thick plates (1-15mm)

6. Nickel-Based Alloys (e.g., Inconel 625)

- Typical applications: High-temperature components (e.g., turbine blades), corrosion-resistant chemical equipment

- Key notes: High cutting difficulty; requires high-power equipment + optimized parameters; suitable for thin-to-medium-thick plates (1-12mm)

(II) Non-Metal Materials: Applicable in Specific Scenarios

While metal processing is the core, certain non-metals can be processed with parameter adjustments and proper safety protection:

1.Acrylic (PMMA)

- Typical applications: Advertising signs, display stands, lamps

- Processing parameters: Reduce laser power + increase cutting speed to avoid melting/adhesion; achieves transparent-edge precision cutting

2.Plastics (e.g., ABS, PC)

- Typical applications: Electronic casings, toy components

- Key requirements: Strict heat input control (prevents deformation/toxic gas emission); mandatory ventilation system; ideal for thin plates (1-5mm)

3.Wood/Plywood

- Typical applications: Model making, decorative crafts

- Processing parameters: Adjust laser focus + cutting speed to avoid burning; suitable for thin plates (1-8mm)

4.Leather/Fabric

- Typical applications: Clothing patterns, shoe materials, luggage

- Processing advantages: Low power + high speed cutting prevents edge charring; enables precise cutting of complex patterns

5.Rubber

- Typical applications: Seals, tire components

- Key notes: Strict cutting depth control to avoid adhesion; suitable for thin layers (1-3mm)

II. Cutting Capabilities & Key Influencing Factors

The processing effect of fiber laser cutting machines primarily depends on equipment power and material characteristics—their compatibility directly determines efficiency and quality.

(I) Correlation Between Equipment Power & Cutting Thickness

- Low-power equipment (<1000W): Suitable for thin plates (1-5mm), mainly used for small parts processing with the advantages of high efficiency and low energy consumption.

- Medium-power equipment (1000-3000W): Applicable to medium-thick plates (5-20mm), which is the mainstream choice for industrial mass production, balancing processing efficiency and precision.

- High-power equipment (>3000W): Capable of cutting thick plates (20mm above); some high-end models can even handle 40mm-thick carbon steel, suitable for large structural parts processing.

(II) Impact of Material Characteristics on Cutting

- High-reflective materials (e.g., pure gold, pure silver): Low laser absorption rate leads to high cutting difficulty

- Flammable materials (e.g., foam, certain plastics): Strict parameter control + enhanced ventilation required to prevent fire/toxic fumes

- Brittle materials (e.g., glass, ceramics): Not suitable for fiber lasers; use alternative lasers (e.g., CO₂ lasers) instead

III. Summary

In conclusion, to select the most suitable fiber laser cutting machine for oneself, various factors such as processing materials and scenarios need to be comprehensively considered. The professional service team of Baokun Laser is always ready to provide you with detailed answers. We wish you a smooth selection process.