Whether you’re a hobbyist exploring creative projects, a small business owner starting a fabrication venture, or a professional manufacturer seeking high-precision production solutions, choosing the right laser cutter is crucial. The market offers a variety of laser cutter types, each with unique strengths tailored to specific materials, applications, and skill levels.

This guide simplifies the selection process, helping you match the perfect model to your needs.

1. Understand the Core Types of Laser Cutters

The primary difference between laser cutters lies in their laser source, which determines wavelength, material compatibility, and performance. The three most common types for beginners to professionals are:

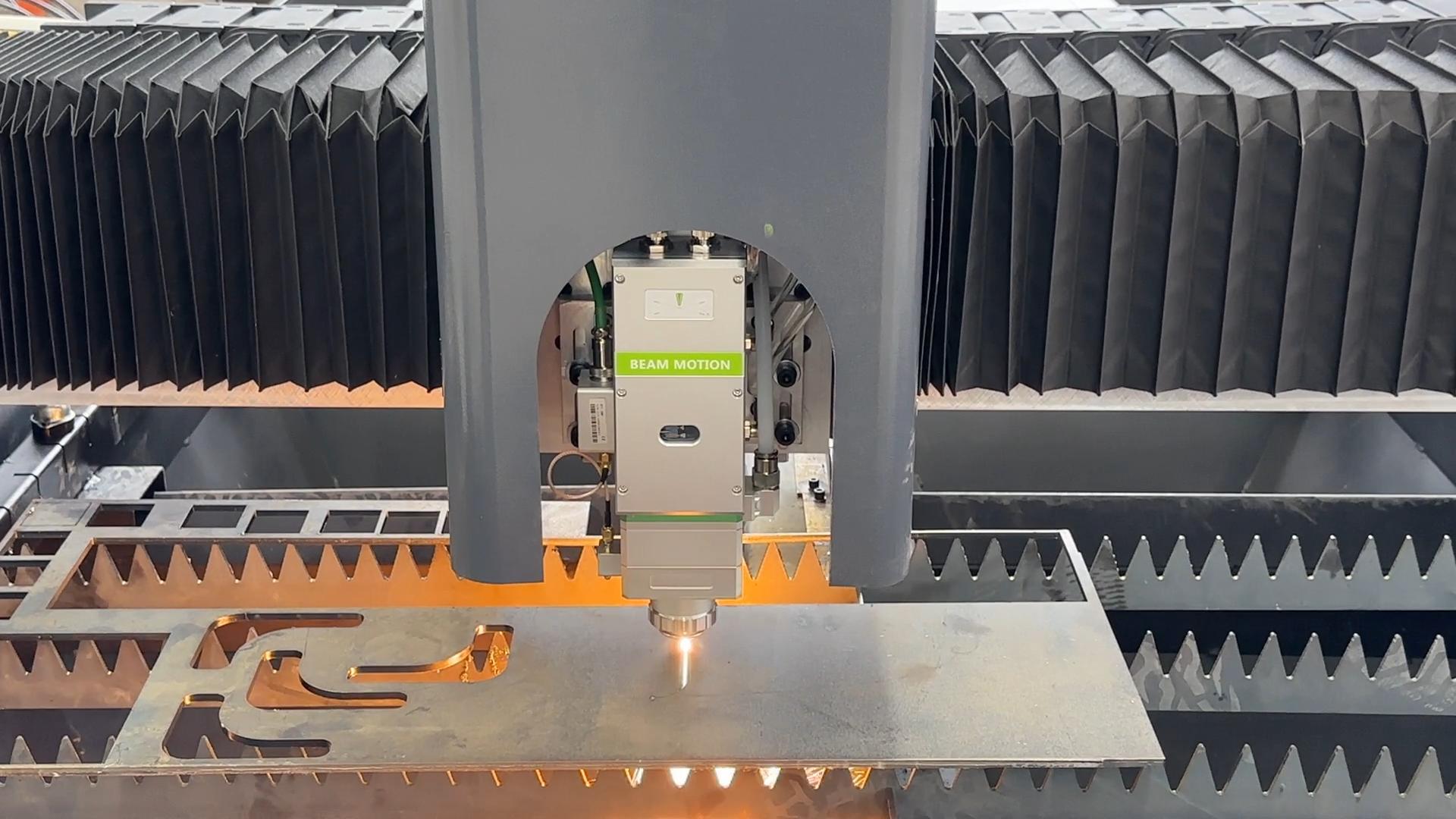

1.1 Fiber Laser Cutters

Fiber laser cutters use a ytterbium-doped fiber as the laser medium, emitting a near-infrared wavelength of 1064 nm. They are the gold standard for metal cutting, boasting an electro-optical conversion efficiency of over 30%—far higher than other types. This translates to faster cutting speeds, lower energy consumption, and minimal maintenance requirements.

-

Suitable for: Carbon steel, stainless steel, aluminum, brass, and other metals. High-power models (10kW+) can handle thick metal sheets up to 50mm, while mid-to-low power options excel at thin metal precision cutting.

-

Best for: Businesses (hardware fabrication, kitchenware production) and professional manufacturers (automotive parts, metal components) focusing on metal processing. Not ideal for non-metallic materials due to low wavelength absorption.

1.2 CO₂ Laser Cutters

CO₂ laser cutters use a mixture of carbon dioxide, nitrogen, and helium to generate a mid-infrared wavelength of 10.6 μm. This wavelength is easily absorbed by non-metallic materials, making them highly versatile for both non-metal and thin metal cutting.

-

Suitable for: Wood, acrylic, leather, fabric, plastic, paper, and thin metals (e.g., within 20mm carbon steel, within 10mm stainless steel). They produce smooth cutting edges, ideal for aesthetic applications.

-

Best for: Beginners (hobbyists, crafters), small businesses (advertising signage, custom gifts), and workshops with mixed material needs. Note that they have higher maintenance costs and lower efficiency compared to fiber lasers for metal cutting.

1.3 UV Laser Cutters

UV laser cutters use gas or crystal to generate a 355 nm ultraviolet wavelength, enabling "cold processing" with minimal thermal impact. They deliver micron-level precision, making them suitable for delicate and heat-sensitive materials.

-

Suitable for: PCB boards, electronic components, ceramic substrates, plastic films (PI, PET), glass, and semiconductor wafers. They can cut ultra-fine lines (less than 20μm) without material damage.

-

Best for: Professional users in high-tech industries (3C consumer electronics, medical devices, semiconductors). They are expensive with low power output, so not recommended for beginners or thick material cutting.

2. Model Matching by User Type & Application

2.1 Beginners & Hobbyists

If you’re new to laser cutting and focus on small-scale creative projects (e.g., custom wood crafts, acrylic decorations, leather engraving), prioritize affordability, ease of use, and safety.

-

Recommended models: Entry-level diode laser cutters or low-power CO₂ laser cutters (40-150W). These machines are compact, easy to assemble, and compatible with user-friendly software. Price ranges from $300 to $1,500, making them budget-friendly for beginners.

-

Key considerations: Working area (ensure it fits your project size), safety features (enclosure, emergency stop), and after-sales support for troubleshooting.

2.2 Small Businesses & Entrepreneurs

For small businesses (e.g., advertising production, custom fabrication, small-batch hardware manufacturing), balance productivity, versatility, and cost-effectiveness.

-

Recommended models: Mid-power CO₂ laser cutters (150-400W) for mixed non-metal and thin metal work, or mid-power fiber laser cutters (500W-2kW) for dedicated metal processing. These models offer larger working areas (1300×2500mm or custom sizes) and higher cutting speeds to handle daily production needs.

-

Key considerations: Processing efficiency, material compatibility, and automation features (e.g., auto-focus, nesting software) to save time and material costs.

2.3 Professional Manufacturers

Professional users (e.g., automotive parts factories, electronic component manufacturers, large-scale metal fabricators) require high precision, high power, and stable performance for mass production or complex processing.

-

Recommended models: High-power fiber laser cutters (3kW-20kW) for thick metal cutting, UV laser cutters for precision electronic components, or ultra-short pulse lasers (picosecond/femtosecond) for hard and brittle materials (e.g., sapphire, ceramic). These machines often feature advanced CNC systems and enclosed processing environments for safety and stability.

-

Key considerations: Cutting accuracy (repeatability ±0.05mm or higher), long-term operational stability, and customized solutions (e.g., 5-axis 3D cutting for complex workpieces).

3. Essential Buying Tips for All Users

-

Define your core materials first: Match the laser type to your primary material (e.g., fiber for metal, CO₂ for non-metal, UV for precision delicate materials) – this is the most critical step.

-

Determine power needs: Higher power enables thicker cutting but increases cost and energy consumption. For example, within 12mm carbon steel can be cut with a 1-2kW fiber laser, while 20mm+ steel requires 6kW+.

-

Consider working area: Choose a working area that accommodates your largest common workpiece to avoid limiting future projects.

-

Check safety & compliance: Ensure the machine meets international safety standards (e.g., laser class 4 protection for fiber lasers). Features like enclosures, exhaust systems, and emergency stops are non-negotiable.

-

Evaluate after-sales support: Laser cutters require regular maintenance – select a supplier with reliable technical support, spare parts availability, and training resources.

Final Summary

Choosing a laser cutter doesn’t have to be overwhelming. key selection principles is match model to skill level, usage scenario, and budget.And test the machine or refer to authentic user reviews before purchasing.You can contact us to recommend personalized laser solutions for you and select the machine model with the best cost performance.