Laser cutting equipment plays a vital role in industrial production and manufacturing, and its application range is wide and expanding. The following are specific application examples of laser cutting technology in several key industries:

Automobile Manufacturing Industry

Laser cutting technology plays an indispensable role in this field. It can accurately cut complex automotive parts such as body panels, chassis parts, interior parts and brake pads, ensuring high efficiency and high quality of production.

Aerospace Field

In aerospace manufacturing, laser cutting technology also shows its excellent performance. It can precisely process special aviation materials such as metal alloys such as titanium alloys, aluminum alloys, nickel alloys and composite materials, providing key support for the manufacture of aerospace vehicles.

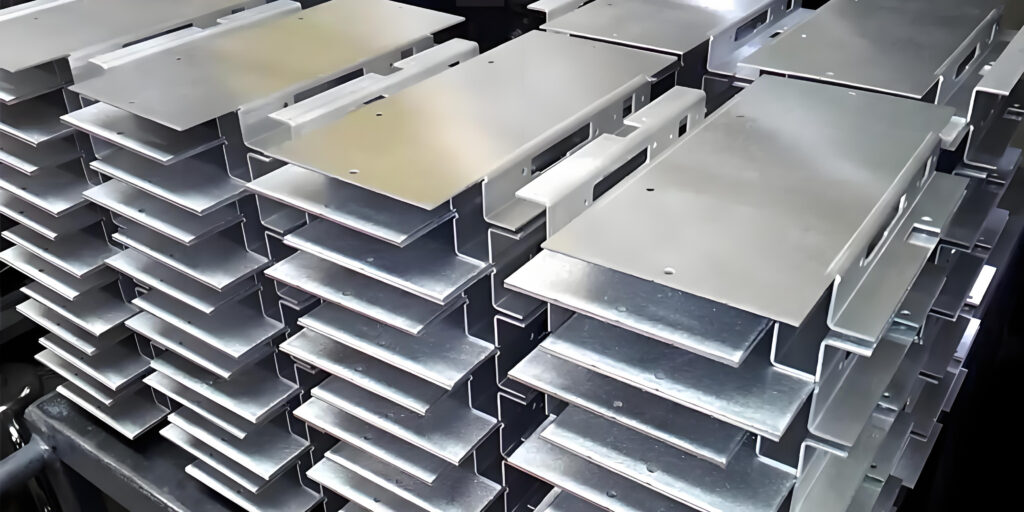

Sheet Metal Processing Industry

Laser cutting technology shows its unique advantages in sheet metal processing. Whether it is electrical cabinets, chassis cabinets, ventilation ducts, or elevator parts, laser cutting can quickly and accurately complete the cutting of complex graphics, greatly improving production efficiency.

Kitchenware and Home Appliance Industry

Laser cutting technology also plays a key role in the manufacture of home appliances and kitchenware. Fine cutting of metal shells and internal structures, as well as sheet metal parts of kitchen equipment such as ovens and refrigerators, are inseparable from the help of laser cutting. It not only improves product quality, but also brings more diversity to the design.

Textile product processing

Laser cutting is also increasingly widely used in the textile industry. Whether it is cloth, leather or yarn, it can be finely processed by laser cutting, providing strong support for the production of high-end clothing, shoes and home accessories.

Advertising and logo industry

The application of laser cutting technology in this field is even more indispensable. The production of stainless steel LOGO, signs, billboards, etc. can achieve accurate and efficient cutting, thereby improving the quality and beauty of advertising products.

Craft gifts and artwork production

Non-metal materials such as wood products, bamboo products, stone, glass, ceramics, and engraving and cutting on certain metal materials can be perfectly presented through laser cutting technology, adding unique charm to the production of crafts and souvenirs.

Architectural model production

In the production of architectural models, laser cutting also shows its excellent performance. The details of the wall, door, window, and roof models can all be made with high precision through laser cutting, thereby improving the efficiency and quality of model making.

Mechanical equipment manufacturing

Laser cutting technology plays a vital role in the manufacturing process of various mechanical equipment. It can process various complex mechanical parts to ensure the high precision and high efficiency of the products.

Rail transportation equipment

Laser cutting is also very useful in the manufacturing of parts for transportation vehicles such as subways and high-speed railways. The cutting and processing of materials such as stainless steel and aluminum alloys cannot be separated from the support of laser cutting technology.

Medical device manufacturing

The production of high-precision medical device components also requires the help of laser cutting technology. It ensures the sanitary conditions of the products while ensuring precise dimensional requirements.

with the continuous advancement of science and technology, the application scope of laser cutting technology continues to expand and deepen. In the future, its application in many fields such as electrical manufacturing, petrochemicals, energy, shipbuilding, and precision instruments will be more extensive and in-depth.