Struggling to manage multiple materials with limited equipment? High costs, slow production, and inconsistent quality are killing your profits. What if one machine could fix it all?

BAOKUN laser cutting machines let small businesses cut metal, acrylic, and composites with precision, speed, and safety. Their industrial-grade design handles thick materials, reduces waste, and works 24/7—all at a fraction of traditional costs.

Let me show you exactly how BAOKUN solves three critical challenges for small workshops. You’ll see why this machine is a game-changer for growing businesses.

1. One Machine, Multiple Materials: How Does BAOKUN Cut Metal, Acrylic, and Composites Precisely?

Buying separate machines for each material drains budgets and floor space. Compromising on quality? That’s not an option anymore.

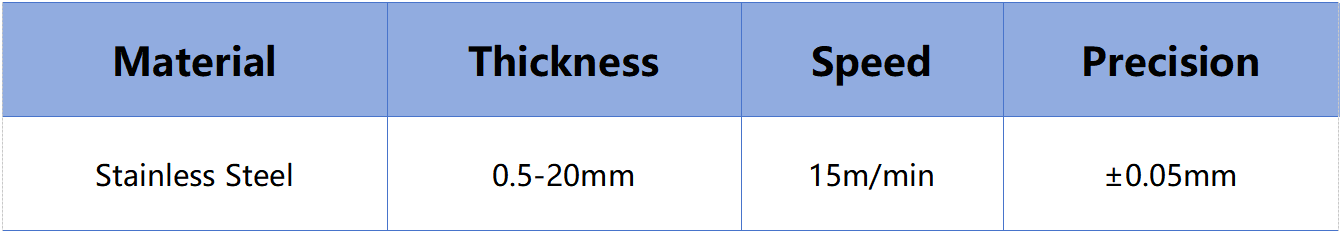

BAOKUN’s fiber laser technology adapts to material properties automatically. It adjusts power, speed, and focal length to cut stainless steel (0.5-20mm), acrylic (1-25mm), and carbon fiber composites without tool changes.

Key Features for Multi-Material Cutting

- Automatic nozzle detection switches gas types (oxygen for steel, nitrogen for acrylic)

- Collision avoidance system prevents damage when cutting uneven surfaces

- Material database stores 200+ preset parameters for fast setup

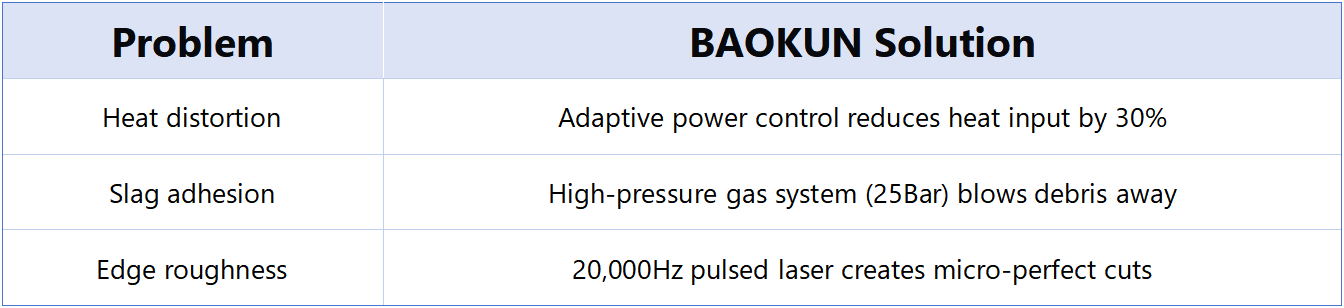

2. Flawless Results: How Does BAOKUN Balance Speed with Perfect Edges?

Burnt edges and rough finishes make clients reject orders. But slowing down production isn’t the answer.

BAOKUN uses real-time temperature monitoring and dual cooling systems. This prevents overheating while maintaining speeds up to 40m/min—even on 15mm stainless steel.

Achieving High Speed + High Quality

Case example:

A jewelry mold maker reduced polishing time by 70% after switching to BAOKUN. Their acrylic molds now have mirror-like edges straight from the machine.

3. 24/7 Operation: Can BAOKUN Handle Heavy Workloads Without Breaking Down?

Downtime costs $500/hour in lost orders. Cheap machines fail when you need them most.

BAOKUN’s industrial components—German rails, Japanese servos, IPG laser source—last 100,000+ hours. Safety sensors and automatic lubrication ensure non-stop production.

Built for Tough Workshops

| Component | Specification | Benefit |

|---|---|---|

| Laser Source | IPG 6kW Fiber | 98% energy efficiency |

| Guide Rails | German Rexroth | 0.003mm positioning repeatability |

| Cooling System | Dual-circuit | 40°C stable operation |

Safety first:

- Fire detection shuts down power in 0.1 seconds

- Dust extraction removes 99% particles

- Light barriers stop operation if doors open

BAOKUN laser machines give small businesses industrial-grade cutting power. Handle diverse materials, boost quality, and run non-stop—all while saving costs. Ready to upgrade? Let’s discuss your needs.