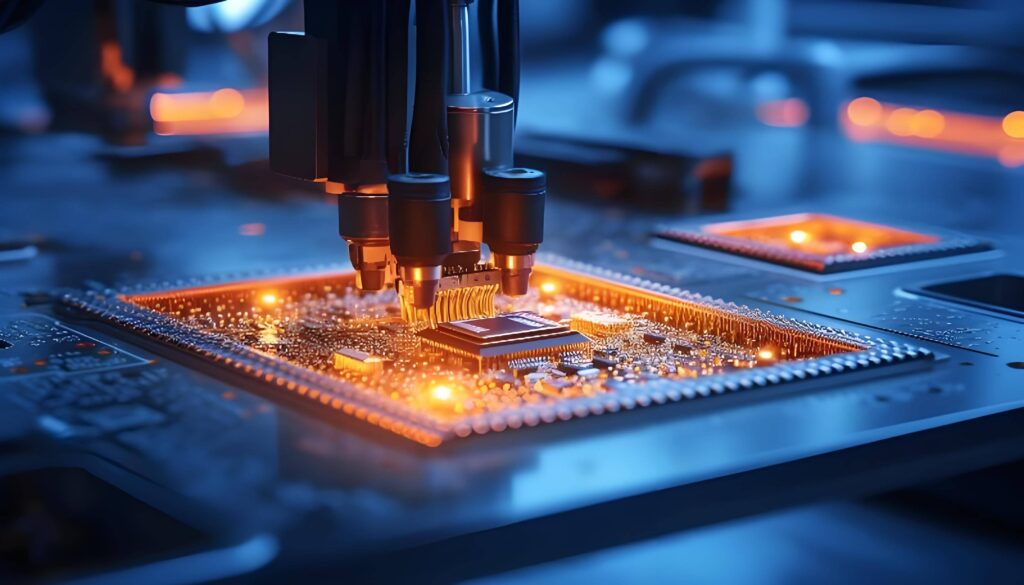

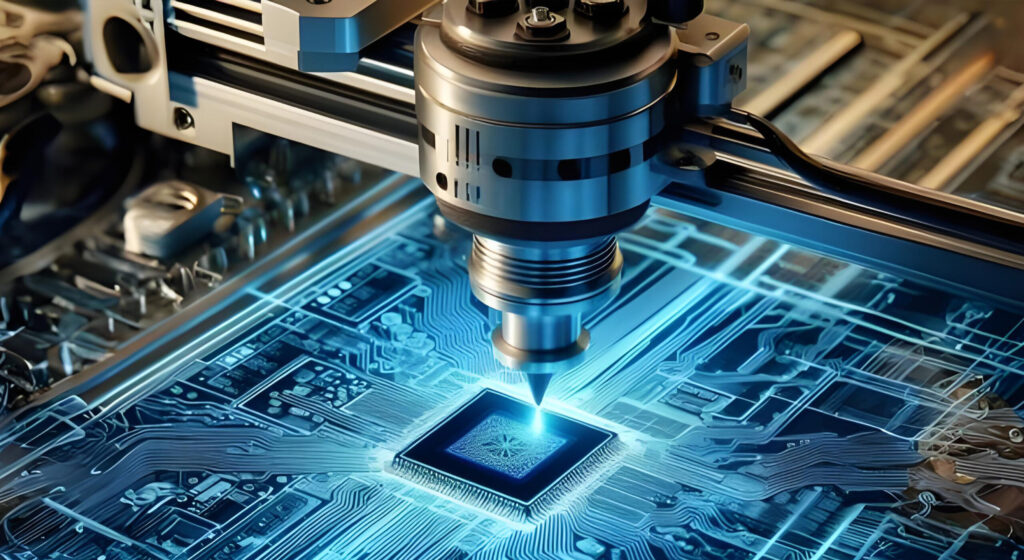

As an advanced processing technology, precision laser cutting boasts advantages such as high flexibility, stress-free non-contact processing and a high level of intellectualization. Featuring narrow kerfs, low material loss and no need for molds, it is applicable to the processing of almost all materials. It has become a core solution for precision manufacturing in various […]

Read More

The global furniture industry thrives on a complete industrial chain and deep integration of technology and manufacturing. Laser pipe cutting machines, with core advantages of high precision and efficiency, cover key links like pipe blanking and complex hole processing, greatly enhancing furniture frame fitting and assembly efficiency, and serving as a core technical support for […]

Read More

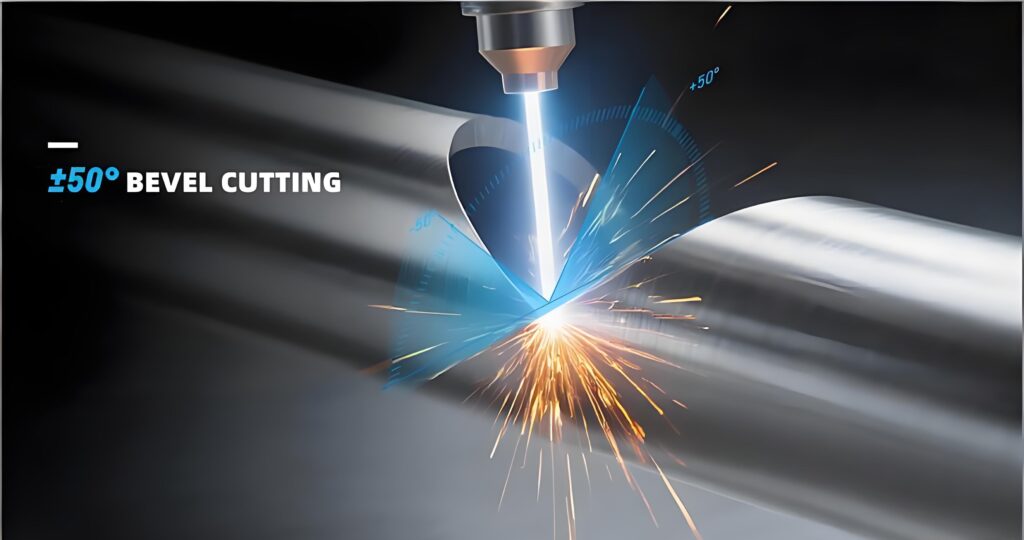

Introduction In pipe welding, structural frame joining and similar fields, smooth angled pipe joints are primarily achieved through bevel cutting. Traditional straight-cut pipe welding is plagued by large gaps, low strength and poor aesthetics. The bevel laser pipe cutting machine effectively addresses this pain point, serving as core equipment for precision machining. I. Bevel […]

Read More

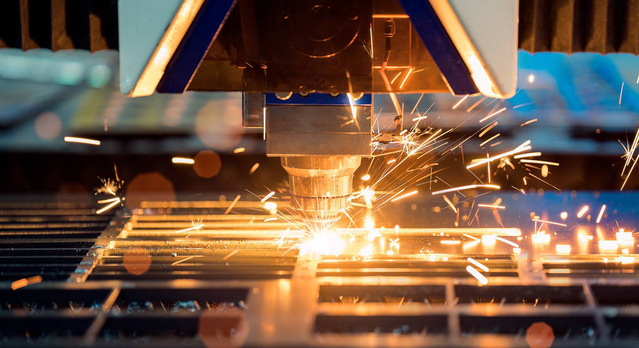

The fiber laser cutting as a highly representative high-efficiency and precision processing equipment in modern manufacturing.Boasting outstanding advantages of high processing efficiency and cutting precision, it is widely applied in processing both metals and certain non-metallic materials. I. Core Applicable Materials: Metals as the Primary Focus, Non-Metals as Supplementary (I) Metal Materials: Core Processing […]

Read More

As industrial manufacturing demands higher precision and efficiency for products, 6kW laser cutting technology has gradually become a core tool in the metal processing industry, thanks to its advantages of high precision, high speed, and strong adaptability. Next, we will explore the principle, advantages, and diverse applications of this technology in depth. 1. Technical […]

Read More

A laser cutter is a valuable business investment, and its performance and lifespan directly affect your productivity and cost-efficiency. Many users neglect daily maintenance, leading to frequent breakdowns, reduced cutting precision, and shortened equipment life. Regular maintenance can significantly extend your laser cutter’s service life by more. Step 1: Clean Optics (Lenses & Mirrors) […]

Read More

Laser cutting is valued for its precision and versatility in processing non-metallic materials, with wood, acrylic, and leather being top choices for crafts, advertising, and custom manufacturing. Many users face issues like charred edges, incomplete cuts, or material deformation due to incorrect parameter settings. The secret to successful laser cutting is matching parameters to material […]

Read More

CO₂ laser cutters are widely used in industries like advertising, crafts, and small-batch manufacturing for their versatility in cutting non-metallic materials (wood, acrylic, leather) and thin metals. However, safe operation and proper maintenance are critical to ensure workplace safety, machine longevity, and consistent cutting performance. This guide focuses on two core aspects: waste gas treatment […]

Read More

Whether you’re a hobbyist exploring creative projects, a small business owner starting a fabrication venture, or a professional manufacturer seeking high-precision production solutions, choosing the right laser cutter is crucial. The market offers a variety of laser cutter types, each with unique strengths tailored to specific materials, applications, and skill levels. This guide simplifies the […]

Read More

Laser sheet metal cutting machines are essential tools in modern manufacturing, favored by factories and businesses for their efficiency and precision. However, for beginners using laser cutting machines for the first time, mastering some operating techniques is essential. This article will introduce 10 beginner tips for laser sheet metal cutting machines to help you master […]

Read More

What is assist gas in laser cutting? What are the differences?

Read More

To achieve high-quality metal cutting, it is important to master key skills

Read More

Let’s take a look at the reasons for the aging of laser cutting machines and their practical solutions

Read More

CO2 lasers are popular with small businesses because they offer unmatched precision, cost-efficiency, and versatility.

Read More

laser cutting machines will lead the manufacturing industry towards a more efficient, smarter and more environmentally friendly future.

Read MoreBaokunBaokun Laser is a top manufacturer of laser cutting equipment. Over the past 20 years, we've been supplying customers from more than 90 countries and regions. OEM ODM acceptable.

ENQUIRY NOW