Model:BKJ-F1325/BKJ-F1530

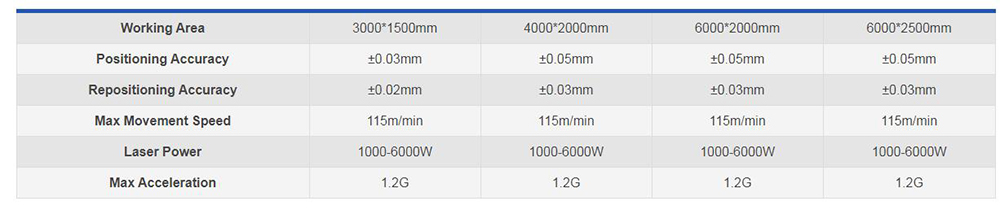

Cutting Area:1500*3000mm/2000*4000mm

Laser Power:1000W-6000W

laser wavelength:1077nm-1083nm

Cooling Type:Water cooling

Cutting Thickness:Depending on materials

Position Type:Red Dot

Operation Mode:CW1000

Power Tuning Range:10%-100%

Operation Voltage:220V/380V

Max Modulation Freq:50Hz/60hZ

The whole machine is fully protected and closed design, safe and environmentally friendly, no pollution, in line with ergonomics and international standards.

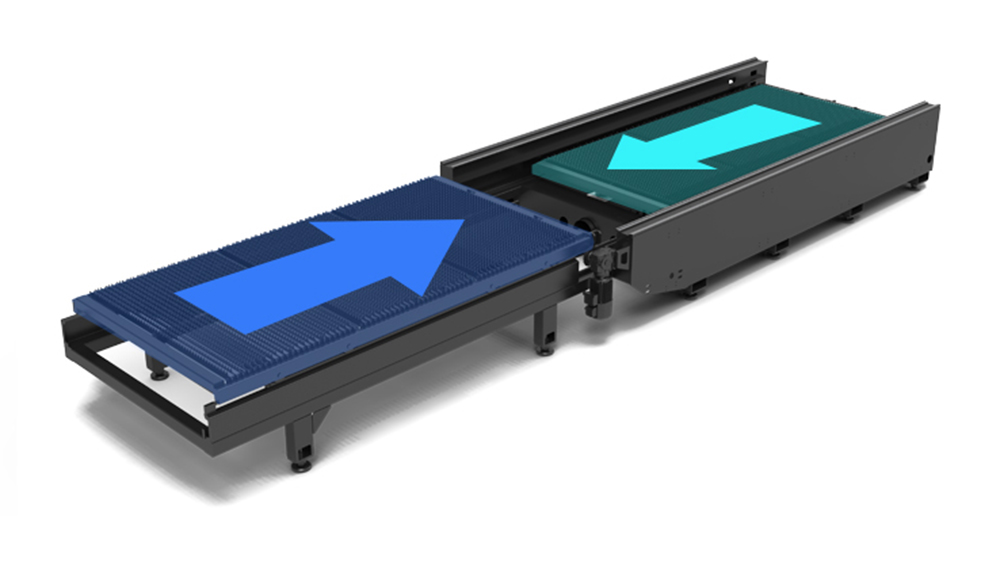

The newly designed parallel exchange locking system has a simple and reliable structure, which makes the processing efficiency high and the stability is good. The dual platform can further improve the production efficiency.

It adopts a gantry structure, a lightweight design, uses aerospace-grade extruded aluminum, and is finished after artificial aging and solution treatment. The gantry has excellent rigidity, surface quality, and integrity. It also has excellent dynamic performance and is conducive to high speed cutting.

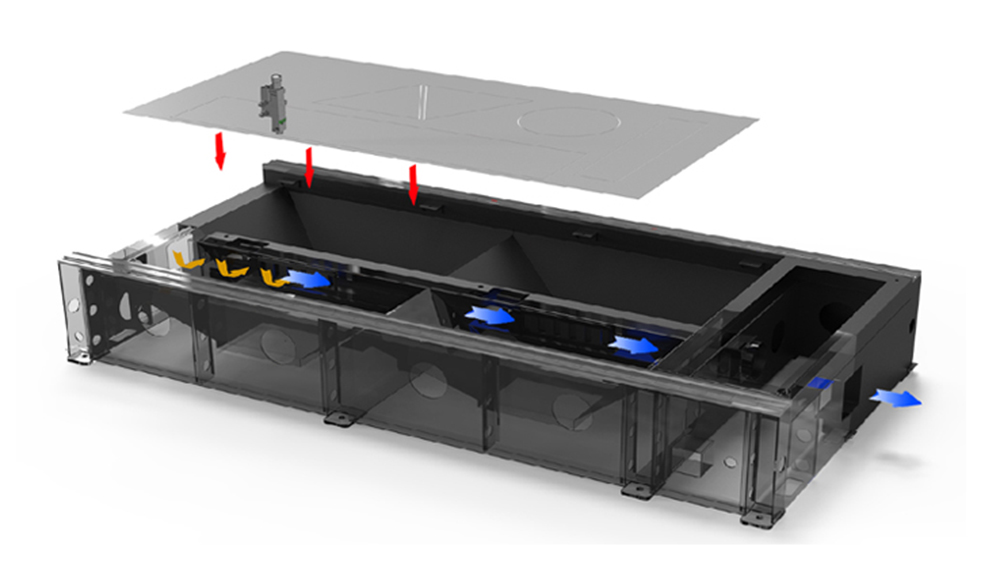

The newly upgraded intelligent partition dust removal system has a more reasonable dust removal design, which effectively increases the ventilation and dust removal effect and prolongs the service life of the equipment.

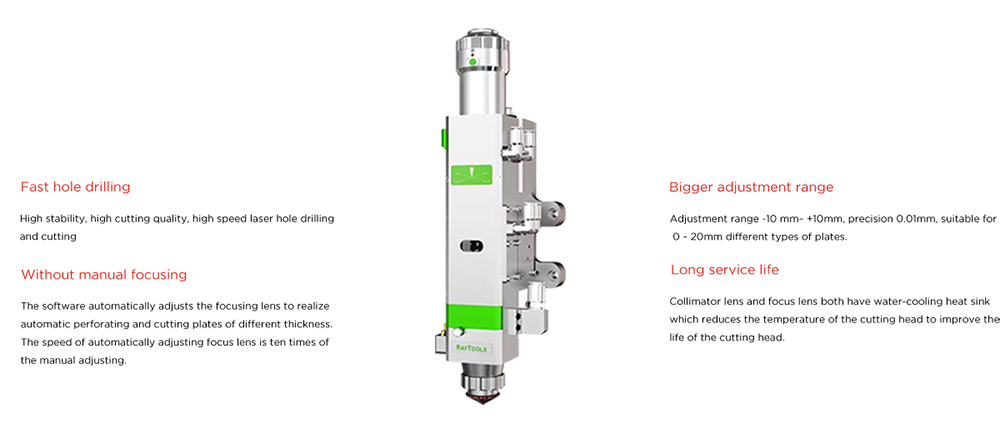

The machine is equipped with an automatic focusing laser head, the focus can be automatically adjusted, and the operation is simple, convenient, fast and accurate. Shorten piercing time, improve piercing quality, high-speed cutting, and save time.

1. The laser metal fabricator adopts gantry type single-side double-drive structure, imported high-precision reducer, gear rack and linear guide, smooth transmission, fast acceleration, Bit precision.

2. Both the bed and the moving beam adopt the whole welded structure. After annealing, rough machining and vibration aging, the welding process can be completely eliminated. Processing of stress, rigidity, high precision, can be maintained for a long time without deformation.

3. X, Y axis with high-precision servo motors, bed movement performance greatly improved, acceleration up to 1.5G, to ensure that the whole machine has high speed and high acceleration performance.

4. Using the Windows operating system based CypCut fiber laser cutting machine dedicated CNC system, integrated a lot of laser cutting control dedicated functions Module, powerful, simple operation.

5. Switzerland RAYTOOLS Laser Head is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

6. Germany high-precision electronic proportional valve, precise control of cutting auxiliary gas pressure, in order to achieve the best cutting results.

This is a fully enclosed fiber laser cutting machine with an exchange table. The fully-protected closed design ensures the safety of processing. The stable parallel exchange table saves labor costs and improves processing efficiency. It has the advantages of fast cutting speed, good cutting effect, low operating cost, and good stable processing ability. Available laser power range is 1000W-6000W.