The best Heavy Duty Type Plasma Cutting Machine with 4×8 table size can cut steel, copper, brass, aluminum, alloy, iron, etc.

Now the Heavy Duty Type Plasma Cutting Machine for sale at affordable price.

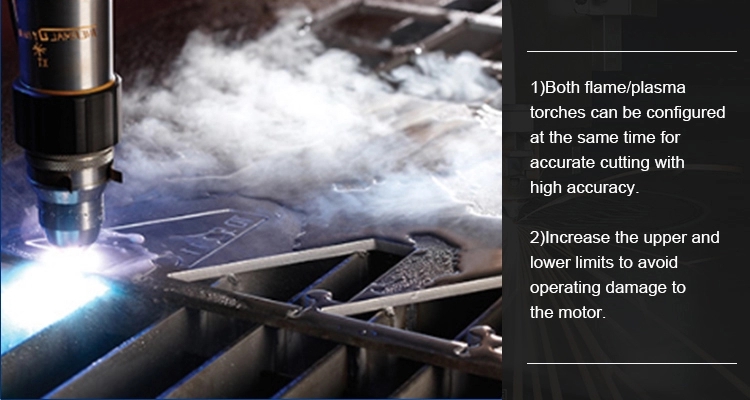

A process for melting (and evaporating) the metal at the notch of the workpiece using

the heat of the high temperature plasma arc and removing the molten metal

by the momentum of the high speed plasma to form the notch.

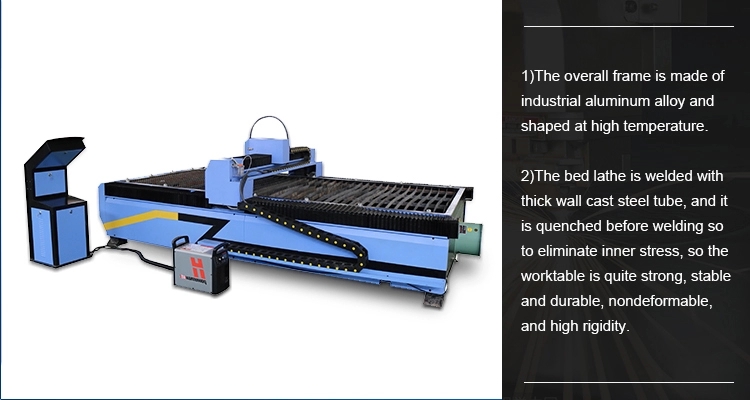

Heavy Duty Type Plasma Cutting Machine

Model :BKP1530, others optional

Working area:1500*3000mm, others optional

Software:Starcam

Working area1500*3000mm

Cutting thickness:0.1-40mm

Working voltage:220/380v

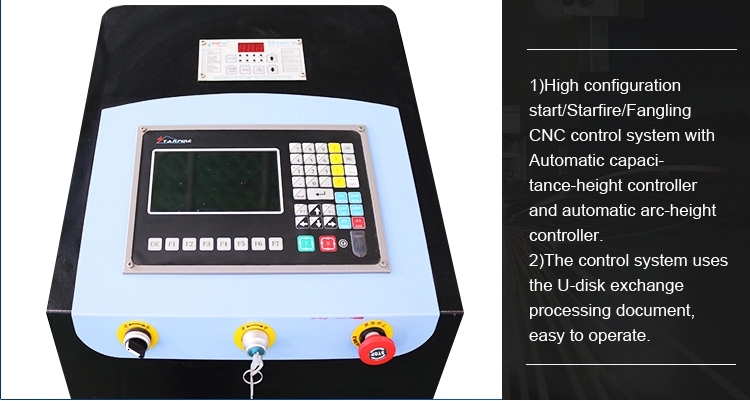

Control system: Start/Starfire

Motor and driver:Leadshine/servo motor optiona

lDocumenttransmission form:USB

Warranty:Two years

ARC/THC

Controller :Including

Power supply :China Huayuan /US hypertherm

Features and Advantages of Best 4×8 CNC plasma cutting machine:

1. The beam uses light structural design, with good rigidity structure, light dead weight and small movement inertia.

2. The gantry structure, X,Y axis all use straight rail that make the machine driving smoothly with high-precision.

3. Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good.

4. Equipped with other advertise equipment, forming the advertising word processing pipe line. Completely solve the traditional manual processing methods.Improve the efficiency of several times.

5. Cutting mouth is small, tidy,and avoid a second dressing processing.

6. The CNC plasma cutting table is used to cut iron sheet, aluminium sheet, galvanized sheet, hundred steel plates, metal plates and so on.

7. High cutting speed, high precision low cost.

8. The numerical control system disposes high, the automatic striking arc, the performance is stable.

9. Support Wentai, Astronautics Haire, ARTCAM softwares.

10. The control system uses the U-disk exchange processing document, easy to operate.

Heavy Duty Type Plasma Cutting Machine